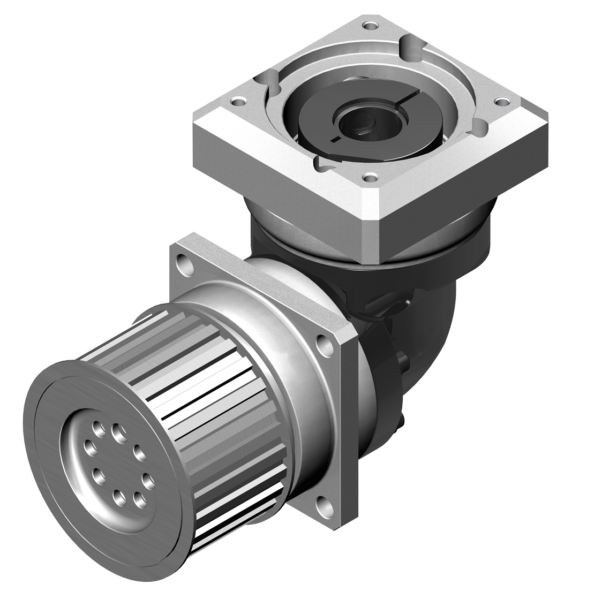

Product Description

Reducer with mineral oil, the transmission efficiency is 87%; if with synthetic oil, the transmission efficiency is 92%.

Blending the most advanced design concept from home and abroad, fluid simulation was carried out on the shell, the structure is optiomized to the utmost.

The special circular structure makes the heat dissipation better.

Using the structure of inhead type. High speed shaft and main shaft oil seal lip were higher than the oil level line. Avoid oil spilling. No oil spill risk.

Using high precision worm gear transmission, the characteristics of damping performance is excellent.

Running with the 43% duty of the rated load (2T cage & 2T load), the temperature rise of the reducer is 45K.

The fever of High speed spindle bearing is the most serious. Torindrive use special high precision ball bearings instead of the commonly used roller bearing and unique internal circulation cooling lubrication system, the cooling effect of reducer is better.

Make full use element analysis (FEA) to analyze the mechanical load, the stress the deformation of the reducer parts. Thus, the reducer structure is designed reasonably, the safety factor is greatly increased and the design life is ensured to more than 8 years.

| Type | weight(kg) | Oil(L) | Gear Ratio | Motor power(kw) |

| EP100-1 | 58 | 3 | 14 | 2×15 |

| EP100-2 | 58 | 3 | 16 | 2×13 |

| EP100-3 | 58 | 3 | 19.5 | 2×11 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery |

|---|---|

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Stepless |

| Samples: |

US$ 699/Piece

1 Piece(Min.Order) | |

|---|

Can you provide real-world examples of products that use pulley gearbox technology?

Pulley gearbox technology finds application in various industries and products where speed reduction, torque multiplication, and efficient power transmission are required. Here are some real-world examples of products that commonly use pulley gearbox technology:

Automotive Industry: Pulley gearboxes are widely used in automotive applications to transmit power and control rotational speed. One prominent example is the continuously variable transmission (CVT) system, which utilizes a pulley gearbox to provide seamless and efficient speed control. CVTs are found in many modern passenger vehicles, where they offer improved fuel efficiency by continuously adjusting the gear ratio to match the driving conditions. Pulley gearboxes are also employed in engine accessory drives, such as alternator drives, air conditioning compressor drives, and power steering systems.

Industrial Machinery: Pulley gearboxes are commonly utilized in various industrial machinery and equipment. Belt-driven machines, such as conveyor systems, packaging equipment, and material handling systems, often incorporate pulley gearboxes to transmit power and control speed. These gearboxes enable efficient power transfer and allow for easy speed adjustment to match specific application requirements. Additionally, pulley gearboxes are used in machine tools, textile machinery, printing presses, and many other industrial applications where precise speed control, torque multiplication, and energy efficiency are essential.

Exercise Equipment: Many types of exercise equipment, including treadmills, elliptical machines, and stationary bikes, utilize pulley gearboxes. These gearboxes are responsible for transmitting power from the motor to the moving components, such as the running belt or pedal assembly. By incorporating pulley gearboxes, exercise equipment manufacturers can provide users with adjustable speed settings and variable resistance levels, allowing for customized workouts and efficient energy utilization.

Home Appliances: Pulley gearboxes can be found in various home appliances where speed reduction and efficient power transmission are required. For example, washing machines often utilize pulley gearboxes to control the drum’s rotational speed during different wash cycles. Similarly, certain types of blenders and mixers use pulley gearboxes to achieve multiple speed settings for food preparation tasks. The gearboxes enable efficient power transfer and allow users to select the desired speed based on the specific application.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems commonly employ pulley gearboxes in their fan assemblies. These gearboxes enable speed control and ensure that the fans operate at the desired rotational speed for efficient air circulation. By adjusting the pulley sizes or gear ratios, the airflow can be optimized to match the cooling or heating demands of the space, resulting in energy savings and improved HVAC system performance.

Farming and Agricultural Equipment: Pulley gearboxes are utilized in various farming and agricultural equipment to transmit power and control rotational speed. Equipment such as combine harvesters, hay balers, and irrigation systems often incorporate pulley gearboxes to drive and control the speed of different components. These gearboxes enable efficient power transmission and help optimize the operation of agricultural machinery for improved productivity and reduced energy consumption.

Power Tools: Pulley gearboxes are also present in certain power tools to provide speed control and torque multiplication. Examples include bench grinders, drill presses, band saws, and woodworking equipment. By incorporating pulley gearboxes, power tool manufacturers can offer users the flexibility to adjust the speed and optimize the tool’s performance for various applications, while ensuring efficient power transfer and reduced power consumption.

Entertainment Industry: In the entertainment industry, pulley gearboxes are utilized in various equipment and devices. Examples include stage machinery for theater productions, where pulley gearboxes are used to control the movement of curtains, scenery, and other stage elements. Pulley gearboxes are also found in amusement park rides, enabling precise speed control and ensuring the safety and enjoyment of the riders.

These are just a few examples of the wide range of products and industries that utilize pulley gearbox technology. The versatility and efficiency of pulley gearboxes make them a valuable component in numerous applications where power transmission, speed control, and energy efficiency are essential.

How do pulley gearboxes handle variations in load and torque during operation?

Pulley gearboxes are designed to handle variations in load and torque during operation by utilizing the mechanical advantage provided by the pulley system and adjusting the pulley ratios. This flexibility allows pulley gearboxes to adapt to changing conditions and maintain consistent performance. Here’s a detailed explanation of how pulley gearboxes handle load and torque variations:

Mechanical Advantage: Pulley gearboxes utilize the principle of mechanical advantage to handle variations in load and torque. The different sizes of the driving and driven pulleys create a mechanical advantage that allows for the transformation of speed and torque. By adjusting the pulley sizes and ratios, the gearbox can modify the mechanical advantage to accommodate different load and torque requirements. This mechanical advantage compensates for variations in load and enables the gearbox to deliver the necessary torque to overcome resistance or deliver power efficiently.

Pulley Configurations: Pulley gearboxes can be designed with various pulley configurations to handle load and torque variations effectively. For example, compound pulley systems can be employed to provide multiple stages of speed reduction or increase, allowing for finer control over torque and speed. Multiple belts or ropes can also be used to distribute the load across several pulleys, reducing stress on individual components and enhancing the gearbox’s ability to handle variations in load and torque.

Adjustable Pulley Systems: Some pulley gearboxes incorporate adjustable pulley systems, such as variable speed drives or tension-adjustable pulleys. These systems allow for on-the-fly adjustment of the pulley sizes or tension, enabling the gearbox to adapt to changing load and torque conditions. By adjusting the pulley ratio or tension, the gearbox can optimize the speed, torque, and power transmission efficiency based on the specific requirements of the application.

Load Sensing and Feedback Mechanisms: In certain applications, pulley gearboxes may be equipped with load sensing and feedback mechanisms. These mechanisms monitor the load or torque being exerted on the gearbox and provide feedback signals that can be used to adjust the pulley ratios or control other aspects of the system. Load sensing and feedback mechanisms help optimize the performance of the gearbox by dynamically responding to variations in load and torque, ensuring efficient power transmission and preventing overload or underload conditions.

System Design and Overload Protection: The overall design of the pulley gearbox can also contribute to its ability to handle variations in load and torque. Robust construction, appropriate selection of materials, and careful engineering considerations ensure that the gearbox can withstand high loads and torque without failure. Additionally, overload protection mechanisms, such as torque limiters or safety clutches, can be incorporated to safeguard the gearbox and other components from damage in the event of sudden or excessive loads.

Regular Maintenance: Proper maintenance practices, including regular inspection, lubrication, and component replacement, are essential for ensuring the optimal performance and longevity of pulley gearboxes. By maintaining the gearbox in good working condition, potential issues that may arise from load and torque variations can be identified and addressed early, reducing the risk of failure and improving overall reliability.

In summary, pulley gearboxes handle variations in load and torque during operation through the mechanical advantage provided by the pulley system, adjustable pulley configurations, load sensing and feedback mechanisms, robust system design, and regular maintenance. These features allow pulley gearboxes to adapt to changing load conditions, deliver the required torque, and ensure efficient power transmission in a wide range of applications.

Can you explain the different types of pulley gearboxes and their specific functions?

There are several different types of pulley gearboxes, each with its specific functions and applications. These variations in design and configuration allow pulley gearboxes to cater to diverse requirements in power transmission and speed control. Here’s an explanation of the different types of pulley gearboxes and their specific functions:

- Fixed Ratio Pulley Gearbox: This type of pulley gearbox consists of two pulleys of different sizes that are fixed to their respective shafts. The driving pulley and the driven pulley are connected by a belt or rope. The fixed ratio pulley gearbox is primarily used for speed conversion, where the rotational speed is either increased or decreased while maintaining a constant ratio between the input and output shafts. It is commonly employed in applications where a specific speed conversion is required, such as in conveyor systems or certain types of machinery.

- Variable Ratio Pulley Gearbox: Also known as a variable speed pulley gearbox or a stepless transmission, this type of gearbox allows for continuous and stepless variation of the speed ratio between the input and output shafts. It typically consists of two conical pulleys connected by a V-belt or a similar mechanism. By adjusting the distance between the two pulleys, the effective diameter of the pulleys changes, resulting in variable speed ratios. Variable ratio pulley gearboxes are commonly used in applications that require smooth and precise speed control, such as in automotive transmissions, industrial machinery, and exercise equipment.

- Compound Pulley Gearbox: A compound pulley gearbox utilizes multiple pulleys arranged in a series or parallel configuration to achieve complex speed and torque conversions. It involves intermediate pulleys and idler pulleys to redirect the belt or rope path. Compound pulley gearboxes offer versatility in speed control and power transmission, allowing for a wide range of speed and torque ratios. They find applications in various industrial systems, including complex machinery, assembly lines, and material handling equipment.

- Reversible Pulley Gearbox: This type of pulley gearbox is designed to provide bidirectional power transmission. It typically consists of two pulleys of the same size connected by a belt or rope. By shifting the belt or rope to different positions on the pulleys, the direction of power transmission can be reversed. Reversible pulley gearboxes are commonly used in applications where the ability to change the direction of rotation is required, such as in winches, hoists, and certain types of machinery.

- Step-Up and Step-Down Pulley Gearbox: Step-up and step-down pulley gearboxes are designed to either increase or decrease the rotational speed and torque between the input and output shafts. Step-up pulley gearboxes have a smaller driving pulley and a larger driven pulley, resulting in higher output speed and lower torque. They are used in applications where high-speed operation is required, such as in certain types of machine tools. Step-down pulley gearboxes have a larger driving pulley and a smaller driven pulley, resulting in lower output speed and higher torque. They are commonly used in applications that require high torque, such as in heavy-duty machinery and equipment.

The specific functions of pulley gearboxes are determined by their design, configuration, and the requirements of the application. By selecting the appropriate type of pulley gearbox, engineers and designers can achieve the desired speed control, power transmission, and adaptability for a wide range of industrial applications.

editor by CX 2024-03-26