Product Description

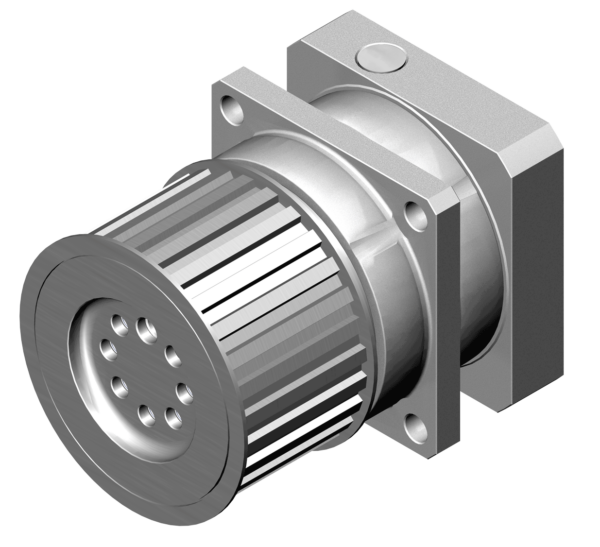

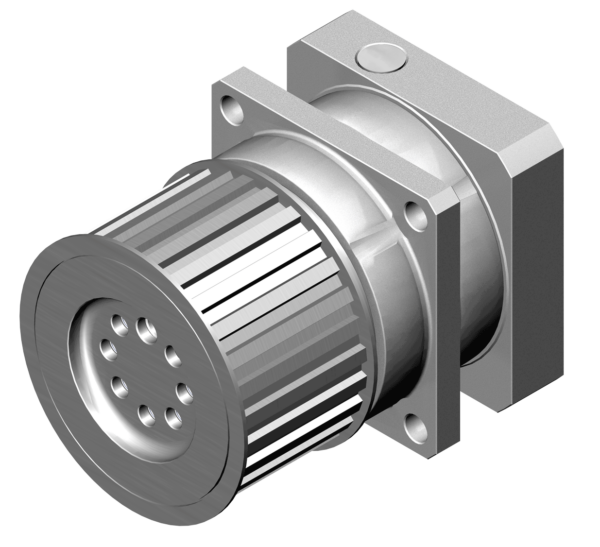

Brushless Gear Reduction Motor Roller Multi Functional Drum Motor for Conveyor

Product Introduction

DGBL series brushless gear reduction motor conveyor roller is 1 of our main roller products, suitable for speed regulation, medium and light load. It is widely used in Automatic Factories, New Energy Companies, Logistics Companies, etc.

Common diameter:ø38, ø50, ø57, ø60, ø67, ø76, ø82, etc.

Product Parameters

There are many different size rollers and the length, material, drive mode could be adjusted based on the customer’s specific requirements. So the listed price is only for your reference, please share us your detailed requirements then we can confirm the price.

Followed is the standard technical data of the DGBL76 for your reference:

Company Profile

ZheJiang Winroller Technology Co., Ltd is a global manufacturer of advanced transmission components, focusing on the development and production of micro and small electric conveyor roller and ultra-precision reducer (≤3 arc minutes).

With over 10 years in this field, we have achieved over 20 patents and enjoyed high popularity among the customers.

Device Support

Based on the product quality first principle, we invested over 6 million USD in processing equipments and inspection devices. Followed are part of pictures for your reference.

Certifications

We have received many patent certifications and CE, ISO certifcate. Followed are the pictures for your reference:

FAQ

Q: Are you trading company?

A: No, we are manufacturer with factory, with over 10 years of production experiences.

Q:How to select a suitable roller?

A:lf you have roller picture and diagram, it would be the best. Or you can tell us the requirements like the load weight, speed, diameter, work voltage, working state, etc.

Q: Do you have a customized service for your standard rollers?

A: Yes, we can customize per your request for the voltage, speed, torque, etc.

Q: Do you have an individual design service for rollers?

A: Yes, we would like to design rollers individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your advantage?

A: We have strong ability of research and development, all the motors and reducers and controllers are self-developed and manufactured. Till now, we have received over 20 patents.

If there is any interest, welcome to contact me.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Galvanizing of Carbon Steel |

| Motor Type: | Built-in Motor |

| Installation: | Horizontal |

| Roller Length: | Customized |

| Power: | 100W/200W/300W |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can pulley gearboxes be customized for specific speed and torque requirements?

Yes, pulley gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer flexibility in designing and configuring pulley gearboxes to suit the specific needs of customers. Here’s a detailed explanation of how pulley gearboxes can be customized for specific speed and torque requirements:

Pulley Size and Configuration: The speed and torque output of a pulley gearbox can be adjusted by selecting the appropriate pulley sizes and configurations. The pulley diameter determines the speed ratio between the input and output shafts of the gearbox. By choosing different pulley sizes, the desired speed reduction or increase can be achieved. Additionally, adjusting the number of pulleys and their arrangement (e.g., single, double, or multiple stages) allows for further customization of the speed and torque characteristics of the gearbox.

Material Selection: The choice of materials for pulleys, belts, and other components in the gearbox can influence the torque capacity and durability. Different materials have varying strength and wear resistance properties, allowing manufacturers to select materials that can handle the specific torque requirements of the application. For higher torque applications, materials with greater strength and durability, such as reinforced belts or pulleys made of steel, may be chosen to ensure reliable performance.

Belt Type and Tension: The type of belt used in the pulley gearbox can impact the speed and torque characteristics. Manufacturers offer a range of belt types, such as V-belts, timing belts, or flat belts, each with different performance characteristics. For example, timing belts with toothed profiles provide precise synchronization and are suitable for applications requiring accurate positioning. Manufacturers can select the appropriate belt type and determine the optimal belt tension to achieve the desired speed and torque transfer while maintaining efficient power transmission.

Motor Selection: The motor driving the pulley gearbox plays a crucial role in determining the speed and torque capabilities of the system. Manufacturers consider the motor’s speed-torque curve, power rating, and other specifications to ensure compatibility with the pulley gearbox. By selecting motors with different characteristics, such as high torque at low speeds or high-speed capabilities, manufacturers can customize the overall system to meet specific speed and torque requirements.

Custom Gear Ratio: In some cases, manufacturers may offer the option to customize the gear ratio of the pulley gearbox by incorporating additional gears or pulley stages. This allows for fine-tuning of the speed and torque output to match the specific requirements of the application. By carefully calculating and designing the gear ratios, manufacturers can optimize the gearbox performance for the desired speed and torque range.

Application-Specific Design: Manufacturers may work closely with customers to understand their unique speed and torque requirements in specific applications. This collaboration enables the customization of pulley gearboxes to meet the exact needs of the application. Factors such as load conditions, duty cycles, ambient environment, and other operational considerations are taken into account to ensure the gearbox is designed and configured appropriately for the specific speed and torque requirements.

It is important to note that customized pulley gearboxes may require additional engineering analysis, such as stress calculations, dynamic simulations, or efficiency assessments, to ensure their performance meets the desired specifications. Collaborating with experienced manufacturers or engineering teams can help ensure the successful customization of pulley gearboxes for specific speed and torque requirements.

How do pulley gearboxes handle variations in load and torque during operation?

Pulley gearboxes are designed to handle variations in load and torque during operation by utilizing the mechanical advantage provided by the pulley system and adjusting the pulley ratios. This flexibility allows pulley gearboxes to adapt to changing conditions and maintain consistent performance. Here’s a detailed explanation of how pulley gearboxes handle load and torque variations:

Mechanical Advantage: Pulley gearboxes utilize the principle of mechanical advantage to handle variations in load and torque. The different sizes of the driving and driven pulleys create a mechanical advantage that allows for the transformation of speed and torque. By adjusting the pulley sizes and ratios, the gearbox can modify the mechanical advantage to accommodate different load and torque requirements. This mechanical advantage compensates for variations in load and enables the gearbox to deliver the necessary torque to overcome resistance or deliver power efficiently.

Pulley Configurations: Pulley gearboxes can be designed with various pulley configurations to handle load and torque variations effectively. For example, compound pulley systems can be employed to provide multiple stages of speed reduction or increase, allowing for finer control over torque and speed. Multiple belts or ropes can also be used to distribute the load across several pulleys, reducing stress on individual components and enhancing the gearbox’s ability to handle variations in load and torque.

Adjustable Pulley Systems: Some pulley gearboxes incorporate adjustable pulley systems, such as variable speed drives or tension-adjustable pulleys. These systems allow for on-the-fly adjustment of the pulley sizes or tension, enabling the gearbox to adapt to changing load and torque conditions. By adjusting the pulley ratio or tension, the gearbox can optimize the speed, torque, and power transmission efficiency based on the specific requirements of the application.

Load Sensing and Feedback Mechanisms: In certain applications, pulley gearboxes may be equipped with load sensing and feedback mechanisms. These mechanisms monitor the load or torque being exerted on the gearbox and provide feedback signals that can be used to adjust the pulley ratios or control other aspects of the system. Load sensing and feedback mechanisms help optimize the performance of the gearbox by dynamically responding to variations in load and torque, ensuring efficient power transmission and preventing overload or underload conditions.

System Design and Overload Protection: The overall design of the pulley gearbox can also contribute to its ability to handle variations in load and torque. Robust construction, appropriate selection of materials, and careful engineering considerations ensure that the gearbox can withstand high loads and torque without failure. Additionally, overload protection mechanisms, such as torque limiters or safety clutches, can be incorporated to safeguard the gearbox and other components from damage in the event of sudden or excessive loads.

Regular Maintenance: Proper maintenance practices, including regular inspection, lubrication, and component replacement, are essential for ensuring the optimal performance and longevity of pulley gearboxes. By maintaining the gearbox in good working condition, potential issues that may arise from load and torque variations can be identified and addressed early, reducing the risk of failure and improving overall reliability.

In summary, pulley gearboxes handle variations in load and torque during operation through the mechanical advantage provided by the pulley system, adjustable pulley configurations, load sensing and feedback mechanisms, robust system design, and regular maintenance. These features allow pulley gearboxes to adapt to changing load conditions, deliver the required torque, and ensure efficient power transmission in a wide range of applications.

How do pulley gearboxes contribute to power transmission and speed control?

Pulley gearboxes play a significant role in power transmission and speed control in mechanical systems. They offer several advantages that contribute to efficient power transmission and precise speed control. Here’s a detailed explanation of how pulley gearboxes contribute to power transmission and speed control:

- Power Transmission: Pulley gearboxes facilitate power transmission between rotating shafts by utilizing belts or ropes and pulleys. The belts or ropes wrap around the pulleys and create a frictional force that transfers power from the driving pulley (input shaft) to the driven pulley (output shaft). The friction between the belts or ropes and the pulleys ensures efficient power transmission without slippage, allowing for the transfer of rotational force and torque from one shaft to another.

- Speed Conversion: Pulley gearboxes enable speed conversion by utilizing pulleys of different sizes. The size of a pulley is determined by its diameter. When the driving pulley has a smaller diameter than the driven pulley, the rotational speed is increased, but the torque is reduced. Conversely, when the driving pulley has a larger diameter than the driven pulley, the rotational speed is decreased, but the torque is increased. By arranging pulleys of different sizes and connecting them with belts or ropes, pulley gearboxes allow for precise speed control and adaptation to specific operational requirements.

- Adjustability: Pulley gearboxes offer adjustability in power transmission and speed control. The sizes of the pulleys can be easily changed to modify the speed and torque ratios. By selecting pulleys of different diameters, the gear ratio can be adjusted to achieve the desired speed and torque output. This adjustability allows for flexibility in adapting to different load conditions, operational requirements, and system constraints.

- Multiple Pulley Configurations: Pulley gearboxes can be designed with multiple pulleys and belts or ropes to create more complex speed and torque conversion systems. These configurations involve additional intermediate pulleys and idler pulleys to redirect the belt or rope path. By combining pulleys of different sizes and arranging them in various configurations, pulley gearboxes can achieve specific speed and torque ratios, allowing for precise control and optimization of power transmission.

- Efficiency: Pulley gearboxes offer high power transmission efficiency. The use of belts or ropes in the pulley system helps absorb shocks and vibrations, resulting in smoother operation and reduced energy losses. The friction between the belts or ropes and the pulleys ensures efficient power transfer without slippage, enabling maximum power transmission from the driving pulley to the driven pulley.

- Smooth Operation: The combination of belts or ropes and pulleys in pulley gearboxes provides smooth operation. The flexibility and elasticity of the belts or ropes help dampen shocks and vibrations, resulting in reduced noise and improved overall system performance. The smooth operation contributes to enhanced user experience, reduced wear and tear on components, and increased system longevity.

Pulley gearboxes offer a reliable and versatile solution for power transmission and speed control in various mechanical systems. Their ability to efficiently transfer power, provide precise speed control, offer adjustability, and facilitate smooth operation makes them suitable for applications where power transmission and speed conversion are essential, such as conveyor systems, industrial machinery, automotive accessories, exercise machines, and more.

editor by CX 2024-04-23