Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

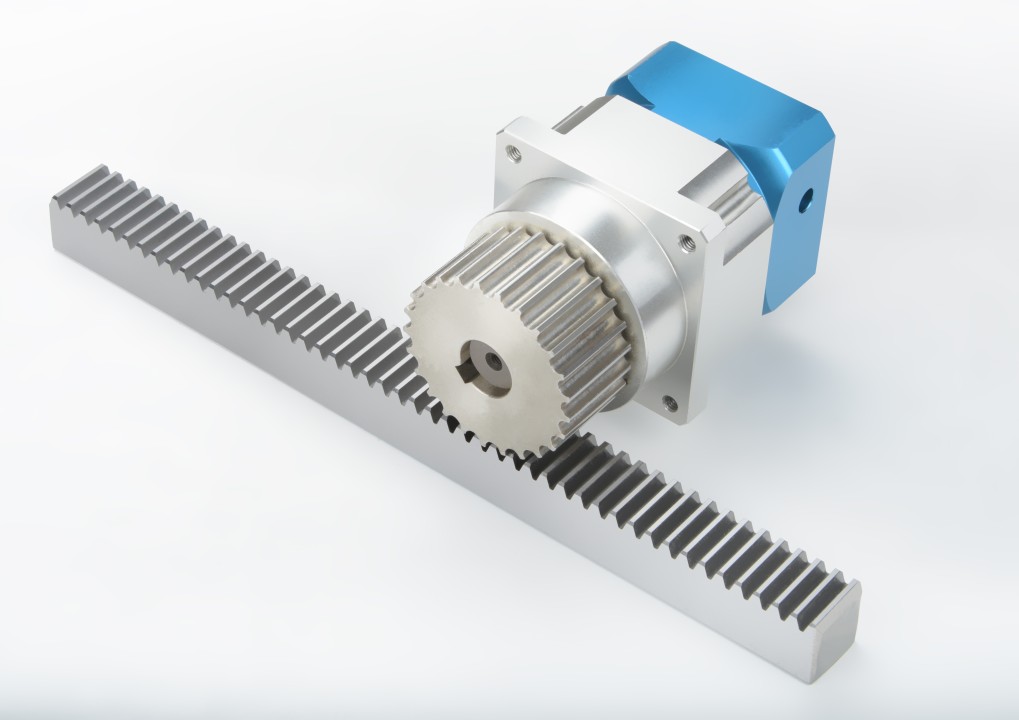

DBY DCY industrial right angle mining 90 degree helical bevel gear gearbox for pulley drum belt

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

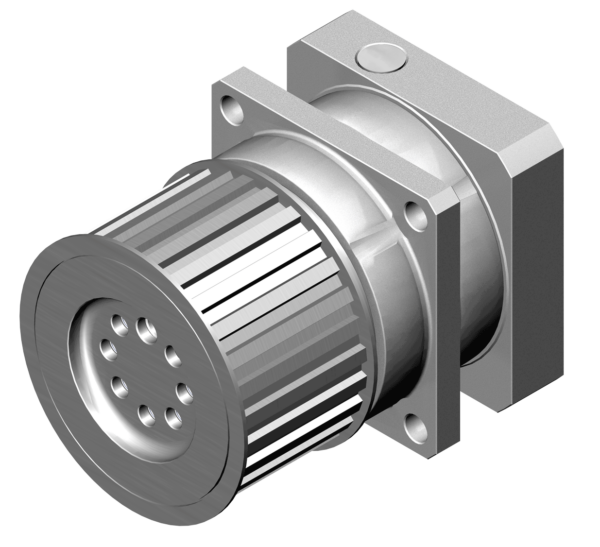

Realized parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes.

Using less component parts.

Applying advanced grinding process which improved the stability and the efficiency of transmit power with lower noise.

Mounting mode:foot-mounted,flange-mounted,swing base-mounted,torque-arm-mounted.

Ratio range:8-50. It will be higher when combining with K&R series reducer.

Product Parameters

|

Type |

Input Speed r/min |

Transmission Ratio |

Type |

Input Speed r/min |

Transmission Ratio |

|

DBY

|

750 |

8 10 11.2 12.5 14 |

DCY

|

750 |

.4 .5 35.5 |

|

1000 |

1000 |

||||

|

1500 |

1500 |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CHINAMFG mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CHINAMFG South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CHINAMFG to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Manufacturing Plant |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Parallel Shaft |

| Samples: |

US$ 1200/Piece

1 Piece(Min.Order) | Order Sample right angle mining 90 degree helical bevel gearbox

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do manufacturers ensure the durability of pulley gearboxes in industrial environments?

Manufacturers take several measures to ensure the durability of pulley gearboxes in industrial environments. These measures involve careful design, material selection, manufacturing processes, and quality control. Here’s a detailed explanation of how manufacturers ensure the durability of pulley gearboxes:

Robust Design: Manufacturers employ robust design practices to ensure that pulley gearboxes can withstand the demands of industrial environments. The gearbox is designed to handle the anticipated loads, torque, and operating conditions specific to the intended application. Factors such as appropriate housing design, proper alignment of pulley shafts, and reinforcement in critical areas are taken into account during the design phase to enhance the durability and reliability of the gearbox.

Material Selection: Careful selection of materials is crucial for ensuring the durability of pulley gearboxes. Manufacturers choose materials that exhibit high strength, wear resistance, and corrosion resistance to withstand the harsh operating conditions in industrial environments. Components such as pulleys, shafts, bearings, and housings are typically made from materials such as steel alloys, cast iron, or aluminum, depending on the specific application requirements and environmental factors.

Quality Manufacturing Processes: Manufacturers employ precise and quality manufacturing processes to produce pulley gearboxes that meet stringent standards. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, ensure accurate dimensions and proper fitment of components. The gearbox components are manufactured with tight tolerances to ensure smooth operation and minimize friction. Additionally, manufacturers follow industry best practices and quality control measures to ensure consistent and reliable production of gearboxes.

Proper Lubrication: Lubrication is critical for the smooth operation and durability of pulley gearboxes. Manufacturers specify appropriate lubricants for the gearbox based on factors such as load, speed, temperature, and operating environment. Adequate lubrication reduces friction, minimizes wear on components, dissipates heat, and helps prevent corrosion. Manufacturers may provide guidelines for the recommended lubrication schedule and type of lubricant to be used, and users are advised to follow these recommendations for optimal gearbox performance and durability.

Testing and Validation: Manufacturers subject pulley gearboxes to rigorous testing and validation procedures to ensure their durability. These tests may include load testing, endurance testing, temperature testing, and performance evaluation under various operating conditions. Testing helps identify potential weaknesses or design flaws, allowing manufacturers to make necessary improvements to enhance the durability and reliability of the gearboxes. Compliance with industry standards and regulations is also an important aspect of the testing and validation process.

Environmental Protection: In industrial environments, pulley gearboxes may be exposed to dust, debris, moisture, or other contaminants that can impact their durability. Manufacturers address this by incorporating protective measures into the gearbox design. This may include sealing mechanisms to prevent ingress of contaminants, such as dust seals or labyrinth seals, as well as the use of coatings or surface treatments to enhance corrosion resistance. These protective measures help extend the lifespan of the gearbox and maintain its performance in challenging environments.

User Education and Support: Manufacturers often provide user manuals, technical documentation, and support to ensure that users understand how to operate and maintain the pulley gearbox properly. This includes information on recommended maintenance practices, lubrication procedures, and troubleshooting guidelines. By educating users about the gearbox’s operational requirements, manufacturers help optimize its durability and minimize the risk of premature failure.

By implementing these measures, manufacturers aim to ensure that pulley gearboxes can withstand the demanding conditions of industrial environments and provide long-lasting, reliable performance.

How do pulley gearboxes ensure efficient power transmission and speed regulation?

Pulley gearboxes employ various mechanisms and design features to ensure efficient power transmission and speed regulation. These elements work together to optimize the transfer of power and enable precise control over the rotational speed. Here’s a detailed explanation of how pulley gearboxes achieve efficient power transmission and speed regulation:

- Pulley Size and Ratio Selection: Pulley gearboxes utilize different pulley sizes and ratios to achieve the desired speed regulation and power transmission efficiency. By selecting appropriate pulley sizes, the gear ratio can be adjusted to match the specific requirements of the application. This ensures that the power is effectively transferred from the driving pulley to the driven pulley, allowing for efficient power transmission.

- Mechanical Advantage: Pulley gearboxes leverage the principle of mechanical advantage to enhance power transmission efficiency. The use of different-sized pulleys creates a mechanical advantage that amplifies the torque output. Larger driving pulleys and smaller driven pulleys result in a higher mechanical advantage, allowing for greater torque transfer. This mechanical advantage ensures efficient power transmission, especially when dealing with varying load conditions.

- Tension and Friction Control: Proper tension and friction control are vital for efficient power transmission in pulley gearboxes. The tension in the belts or ropes connecting the pulleys is adjusted to ensure a firm grip and prevent slippage. Adequate tension helps maximize power transfer efficiency. The friction between the belts or ropes and the pulleys is also optimized to facilitate smooth power transmission. The right amount of friction ensures effective torque transfer while minimizing energy losses.

- Material Selection: The choice of materials for the pulleys, belts or ropes, and other gearbox components plays a crucial role in efficient power transmission. High-quality materials with low friction coefficients and high tensile strength are used to reduce energy losses and minimize wear. The materials are selected based on the specific application requirements to ensure optimal performance and durability.

- Alignment and Belt Tracking: Proper alignment of the pulleys and accurate belt tracking contribute to efficient power transmission and speed regulation. Misalignment and incorrect belt tracking can lead to increased friction, energy losses, and premature wear. Pulley gearboxes are designed with features that facilitate easy alignment adjustment and belt tracking to maintain optimal power transmission efficiency.

- Efficiency Optimization: Pulley gearboxes undergo design optimizations to maximize power transmission efficiency. This includes reducing frictional losses through the use of high-quality bearings, improved lubrication systems, and efficient sealing mechanisms. Minimizing internal losses within the gearbox components helps ensure efficient power transmission and speed regulation.

- Speed Control Mechanisms: Pulley gearboxes often incorporate speed control mechanisms to regulate the rotational speed of the driven pulley. These mechanisms can include adjustable pulley systems, variable speed drives, or additional gear stages. By providing the ability to adjust the speed ratio, pulley gearboxes enable precise speed regulation and accommodate varying operational requirements.

Overall, pulley gearboxes ensure efficient power transmission and speed regulation through a combination of pulley size and ratio selection, mechanical advantage, tension and friction control, material selection, alignment and belt tracking, efficiency optimization, and speed control mechanisms. These design elements work together to optimize power transfer, minimize energy losses, and provide reliable speed regulation in a wide range of applications.

How do pulley gearboxes contribute to power transmission and speed control?

Pulley gearboxes play a significant role in power transmission and speed control in mechanical systems. They offer several advantages that contribute to efficient power transmission and precise speed control. Here’s a detailed explanation of how pulley gearboxes contribute to power transmission and speed control:

- Power Transmission: Pulley gearboxes facilitate power transmission between rotating shafts by utilizing belts or ropes and pulleys. The belts or ropes wrap around the pulleys and create a frictional force that transfers power from the driving pulley (input shaft) to the driven pulley (output shaft). The friction between the belts or ropes and the pulleys ensures efficient power transmission without slippage, allowing for the transfer of rotational force and torque from one shaft to another.

- Speed Conversion: Pulley gearboxes enable speed conversion by utilizing pulleys of different sizes. The size of a pulley is determined by its diameter. When the driving pulley has a smaller diameter than the driven pulley, the rotational speed is increased, but the torque is reduced. Conversely, when the driving pulley has a larger diameter than the driven pulley, the rotational speed is decreased, but the torque is increased. By arranging pulleys of different sizes and connecting them with belts or ropes, pulley gearboxes allow for precise speed control and adaptation to specific operational requirements.

- Adjustability: Pulley gearboxes offer adjustability in power transmission and speed control. The sizes of the pulleys can be easily changed to modify the speed and torque ratios. By selecting pulleys of different diameters, the gear ratio can be adjusted to achieve the desired speed and torque output. This adjustability allows for flexibility in adapting to different load conditions, operational requirements, and system constraints.

- Multiple Pulley Configurations: Pulley gearboxes can be designed with multiple pulleys and belts or ropes to create more complex speed and torque conversion systems. These configurations involve additional intermediate pulleys and idler pulleys to redirect the belt or rope path. By combining pulleys of different sizes and arranging them in various configurations, pulley gearboxes can achieve specific speed and torque ratios, allowing for precise control and optimization of power transmission.

- Efficiency: Pulley gearboxes offer high power transmission efficiency. The use of belts or ropes in the pulley system helps absorb shocks and vibrations, resulting in smoother operation and reduced energy losses. The friction between the belts or ropes and the pulleys ensures efficient power transfer without slippage, enabling maximum power transmission from the driving pulley to the driven pulley.

- Smooth Operation: The combination of belts or ropes and pulleys in pulley gearboxes provides smooth operation. The flexibility and elasticity of the belts or ropes help dampen shocks and vibrations, resulting in reduced noise and improved overall system performance. The smooth operation contributes to enhanced user experience, reduced wear and tear on components, and increased system longevity.

Pulley gearboxes offer a reliable and versatile solution for power transmission and speed control in various mechanical systems. Their ability to efficiently transfer power, provide precise speed control, offer adjustability, and facilitate smooth operation makes them suitable for applications where power transmission and speed conversion are essential, such as conveyor systems, industrial machinery, automotive accessories, exercise machines, and more.

editor by CX 2024-01-10