Product Description

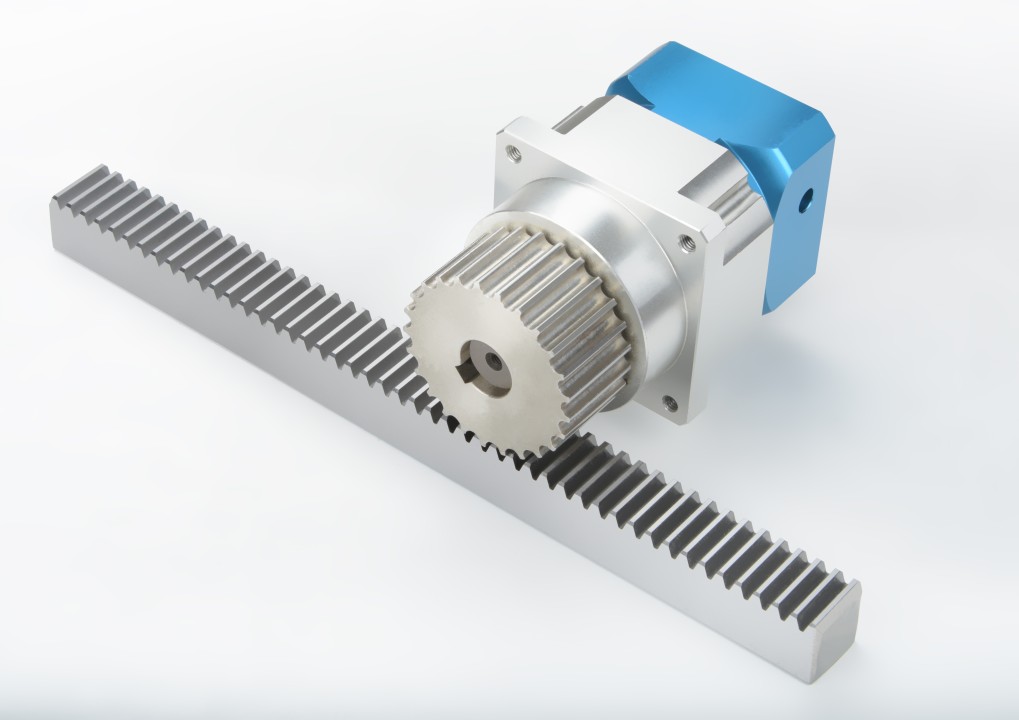

Helical Gear High Precision Planetary Gear Box For 1500W Servo motor Small Gearbox manufacture

Detailed Photos

Product Description

High precision planetary gearbox matched with serve motor, stepping motor are widely used. Lowest backlash<3"); High output torques; High efficiency(96%); Honed toothings; 22 ratios I=3, …., 512; Low noise(<65dB(A)); Any mounting position; Easy motor mounting; Life time lubrication; Figure diameters 40, 60, 80, 120, 160mm. More options.

Planetary gearbox:

ZDE: Precision planetary-round flange output

ZDF: Precision planetary-square flange output

ZDWE: Precise planetary-right angle round flange output

ZDWF: Precise planetary-right angle square flange output

ZDS: Precise planetary-high rigidity, low back lash

ZDR: Helical Gear High Precision Planetary Gear Box

Product Parameters

| Rated output torque | N. M | 4.5-1800 |

| Instant stop torque | N. M | Two times of rated output torque |

| Life | Hour | 30, 000 |

| Full load efficiency | 90%, 94%, 96% | |

| Operating temperature | ° C | -25—+90 |

| IP | IP54 | |

| Lubrication type | Lifetime lubrication | |

| Mounting type | Any |

| Product type | PL40 | PL60 | PL80 | PL120 | PL1600 | |

| Torsional stiffness | N. M/arcmin | 0.7 | 1.8 | 4.5 | 12 | 38 |

| Noise | dB(A) | 55 | 58 | 60 | 65 | 70 |

| Max output speed | Min | 10000 | 8000 | 6000 | 6000 | 6000 |

| Recommend input speed | Min | 4500 | 4000 | 4000 | 4000 | 3000 |

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you ! /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Power |

|---|---|

| Phase: | Single |

| Certification: | CCC, CE, UL. RoHS |

| Brand: | ZD MOTOR |

| Reduction Ratio: | 9 |

| Power of Servo Motor: | 1500W |

| Customization: |

Available

| Customized Request |

|---|

How do pulley gearboxes contribute to optimizing the efficiency of conveyor systems?

Pulley gearboxes play a crucial role in optimizing the efficiency of conveyor systems, which are widely used in industries for material handling and transportation. By providing speed control, torque multiplication, and efficient power transmission, pulley gearboxes offer several benefits that contribute to the overall efficiency of conveyor systems. Here’s a detailed explanation of how pulley gearboxes optimize conveyor system efficiency:

Speed Control: One of the key advantages of pulley gearboxes in conveyor systems is their ability to control the rotational speed of the conveyor belt. By adjusting the pulley sizes or changing the gear ratio, the speed of the conveyor belt can be precisely regulated to match the specific requirements of the application. This speed control capability allows for optimal material handling, preventing unnecessary energy consumption or strain on the system. For instance, in situations where lighter loads or delicate materials are being transported, the speed can be reduced to avoid excessive impact or spillage. On the other hand, for heavy loads or time-sensitive operations, the speed can be increased to maximize productivity. By adapting the speed to the specific needs of the material and operation, pulley gearboxes optimize the efficiency of conveyor systems.

Torque Multiplication: Pulley gearboxes are designed to provide torque multiplication, allowing higher torque to be delivered at the output pulley compared to the input pulley. This torque multiplication capability is particularly beneficial in conveyor systems that handle heavy loads or encounter resistance during operation. By multiplying the torque, pulley gearboxes enable the conveyor system to overcome these challenges more effectively, reducing the risk of belt slippage or motor overload. The increased torque also allows for the use of smaller and more efficient motors, contributing to energy savings and improved efficiency. Torque multiplication provided by pulley gearboxes ensures that the conveyor system operates at its optimal performance level, enhancing overall efficiency.

Efficient Power Transmission: Pulley gearboxes utilize belts or chains to transmit power from the input pulley to the output pulley. These flexible power transmission elements offer several advantages for conveyor systems. Firstly, they absorb vibrations and dampen shocks, reducing the impact on the system components and improving overall reliability. Secondly, belts or chains allow for slight misalignments and flexibility in the conveyor system, compensating for variations and ensuring smooth operation. Furthermore, the use of belts or chains helps to minimize noise generation during operation. Overall, the efficient power transmission provided by pulley gearboxes ensures minimal power losses and maximizes the energy transfer to the conveyor belt, optimizing the efficiency of the system.

Load Matching: Conveyor systems often encounter variations in load conditions, with different weights and types of materials being transported. Pulley gearboxes enable load matching by allowing for the adjustment of speed and torque output to match the specific load requirements. By selecting the appropriate pulley sizes or gear ratios, the pulley gearbox can be optimized to deliver the necessary speed and torque for efficient material handling. This load matching capability ensures that the conveyor system operates at its most efficient point, minimizing energy losses and reducing power consumption. It also helps to prevent unnecessary wear and tear on the system components, prolonging their lifespan and reducing maintenance requirements.

System Integration: Pulley gearboxes are integrated components within conveyor systems, designed to work seamlessly with other system elements. This integration allows for efficient power transfer and synchronization between the motor, pulleys, and conveyor belt. The proper selection and sizing of pulley gearboxes, along with other components such as motors, bearings, and belts, contribute to the overall efficiency of the conveyor system. By ensuring that all system elements work together harmoniously, pulley gearboxes optimize the performance and energy consumption of the conveyor system as a whole.

Maintenance and Reliability: Efficient maintenance practices and reliable operation are crucial for optimizing the efficiency of conveyor systems. Pulley gearboxes are designed to be durable and require minimal maintenance. Regular inspection and lubrication of the gearboxes help ensure smooth operation and minimize friction losses. Additionally, pulley gearboxes are often equipped with features such as seals and guards to protect against contaminants and prevent premature wear. By maintaining the reliability and performance of the pulley gearboxes, conveyor systems can operate at their highest efficiency, reducing downtime and optimizing productivity.

In summary, pulley gearboxes contribute to optimizing the efficiency of conveyor systems by providing speed control, torque multiplication, efficient power transmission, load matching, and seamless integration with other system components. By leveraging these advantages, conveyor systems can operate at their optimal performance levels, minimizing energy consumption, reducing downtime, and maximizing productivity.

What factors should be considered when selecting the right pulley gearbox for an application?

When selecting the right pulley gearbox for an application, several factors need to be considered to ensure optimal performance, efficiency, and compatibility. Here’s a detailed explanation of the factors that should be taken into account:

- Load Requirements: One of the primary factors to consider is the load requirements of the application. This includes factors such as the magnitude of the load, whether it is a constant or variable load, and the torque requirements. Understanding the load characteristics helps determine the appropriate pulley sizes, gear ratios, and torque capabilities needed for the gearbox.

- Speed Requirements: The desired speed range and speed control requirements are crucial considerations. Determine the required speed ratios and the range of speeds the application demands. This helps in selecting the appropriate pulley sizes and configurations to achieve the desired speed variations and control.

- Space Constraints and Design: Consider the available space for installing the pulley gearbox. Assess the dimensions and design of the gearbox to ensure it can be accommodated within the given space constraints. Additionally, evaluate the mounting options and compatibility with the application’s mechanical layout.

- Efficiency and Power Transmission: Evaluate the efficiency of the pulley gearbox to ensure minimal power losses during transmission. Higher efficiency contributes to better overall system performance and reduced energy consumption. Consider factors such as friction losses, belt or rope materials, and the quality of the pulley gearbox components.

- Environmental Factors: Take into account any environmental conditions that may impact the performance and longevity of the pulley gearbox. Factors such as temperature extremes, humidity, dust, and corrosive substances should be considered. Choose a pulley gearbox with appropriate sealing, cooling mechanisms, and materials that can withstand the specific environmental conditions of the application.

- Operational Durability and Maintenance: Consider the expected duty cycle and operational lifespan of the pulley gearbox. Assess the reliability, durability, and maintenance requirements of the gearbox components, including bearings, lubrication systems, and seals. A gearbox that requires minimal maintenance and offers long-term reliability can contribute to cost savings and uninterrupted operation.

- Budget and Cost: Evaluate the budget constraints and cost-effectiveness of the pulley gearbox. Compare different options, considering factors such as initial purchase cost, maintenance requirements, and potential energy savings. Balancing the desired performance with the available budget is essential in selecting the right pulley gearbox.

- Application-Specific Considerations: Lastly, consider any application-specific requirements or standards that need to be met. Certain industries or applications may have specific regulations or performance criteria that the pulley gearbox must adhere to. Ensure that the selected gearbox meets the necessary standards and requirements.

By carefully considering these factors, it becomes possible to select the right pulley gearbox that meets the specific requirements of the application, ensuring optimal performance, efficiency, and longevity.

How do pulley gearboxes handle variations in speed ratios and torque requirements?

Pulley gearboxes are designed to handle variations in speed ratios and torque requirements by utilizing different pulley sizes, configurations, and mechanical principles. They offer flexibility and adaptability in adjusting speed and torque according to specific application needs. Here’s a detailed explanation of how pulley gearboxes handle variations in speed ratios and torque requirements:

Pulley Size and Configuration:

Pulley gearboxes employ pulleys of different sizes and configurations to achieve the desired speed ratios and torque requirements. By varying the diameters of the driving and driven pulleys, the rotational speed can be adjusted. Larger driving pulleys and smaller driven pulleys result in a higher speed ratio, while smaller driving pulleys and larger driven pulleys lead to a lower speed ratio. The selection of pulley sizes allows for precise control over speed variations in pulley gearboxes.

Mechanical Advantage:

The mechanical advantage provided by pulley gearboxes allows them to handle variations in torque requirements. Pulley gearboxes utilize the principle of mechanical advantage, where the larger pulley transfers more torque to the smaller pulley. This allows the gearbox to increase or decrease the torque output while maintaining a consistent speed ratio. By adjusting the pulley sizes and the mechanical advantage, pulley gearboxes can match the torque requirements of the driven machinery or system.

Tension and Friction:

Tension and friction play a crucial role in how pulley gearboxes handle variations in speed ratios and torque requirements. The tension in the belts or ropes connecting the driving and driven pulleys helps maintain a firm grip and prevent slippage, ensuring reliable power transmission. By adjusting the tension, the efficiency of power transmission can be optimized. The friction between the belts or ropes and the pulleys also contributes to the handling of torque variations. The frictional force allows for the transfer of torque from the driving pulley to the driven pulley, accommodating changes in torque requirements.

Adjustability:

Pulley gearboxes offer adjustability, allowing for variations in speed ratios and torque requirements. The pulleys can be moved or adjusted to change the effective diameter or position, altering the speed and torque output. This adjustability enables precise control over the performance of the gearbox, making it adaptable to different operational needs and load conditions.

Compound Pulley Systems:

Compound pulley systems are another mechanism used in pulley gearboxes to handle variations in speed ratios and torque requirements. These systems consist of multiple pulleys arranged in series or parallel configurations, incorporating intermediate pulleys and idler pulleys. The compound pulley systems allow for complex speed and torque conversions, providing a wider range of speed ratios and torque capabilities.

Overall, pulley gearboxes handle variations in speed ratios and torque requirements through a combination of pulley size and configuration, mechanical advantage, tension and friction control, adjustability, and the utilization of compound pulley systems. These features enable pulley gearboxes to efficiently transmit power, control speed, and adapt to different operational demands in a wide range of industrial applications.

editor by CX 2024-02-02