Product Description

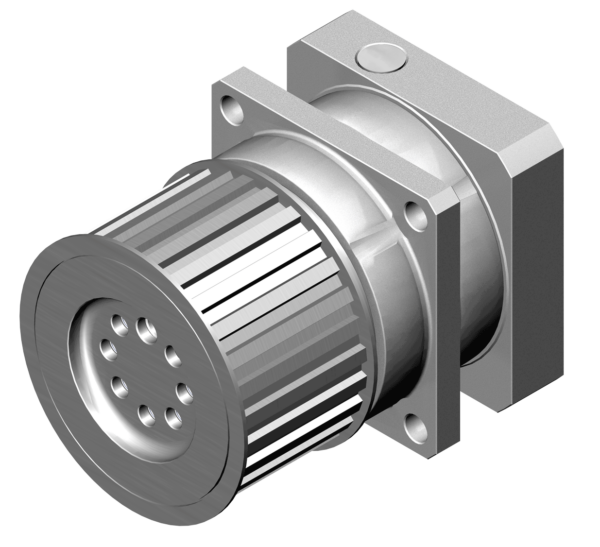

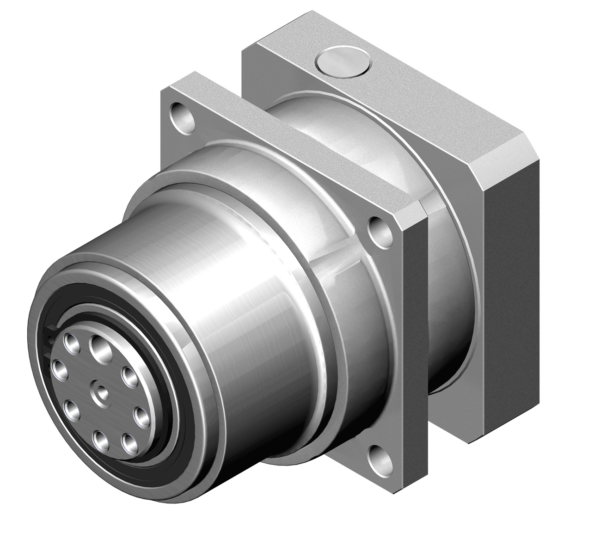

Helical Gear High Precision Planetary Gear Box For 1500W Servo motor Small Gearbox manufacture

High precision planetary gearbox matched with serve motor, stepping motor are widely used. Lowest backlash<3"); High output torques; High efficiency(96%); Honed toothings; 22 ratios I=3, …., 512; Low noise(<65dB(A)); Any mounting position; Easy motor mounting; Life time lubrication; Figure diameters 40, 60, 80, 120, 160mm. More options.

Planetary gearbox:

ZDE: Precision planetary-round flange output

ZDF: Precision planetary-square flange output

ZDWE: Precise planetary-right angle round flange output

ZDWF: Precise planetary-right angle square flange output

ZDS: Precise planetary-high rigidity, low back lash

ZDR: Helical Gear High Precision Planetary Gear Box

| Rated output torque | N. M | 4.5-1800 |

| Instant stop torque | N. M | Two times of rated output torque |

| Life | Hour | 30, 000 |

| Full load efficiency | 90%, 94%, 96% | |

| Operating temperature | ° C | -25—+90 |

| IP | IP54 | |

| Lubrication type | Lifetime lubrication | |

| Mounting type | Any |

| Product type | PL40 | PL60 | PL80 | PL120 | PL1600 | |

| Torsional stiffness | N. M/arcmin | 0.7 | 1.8 | 4.5 | 12 | 38 |

| Noise | dB(A) | 55 | 58 | 60 | 65 | 70 |

| Max output speed | Min | 10000 | 8000 | 6000 | 6000 | 6000 |

| Recommend input speed | Min | 4500 | 4000 | 4000 | 4000 | 3000 |

Company Information

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you ! /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Power |

|---|---|

| Phase: | Single |

| Certification: | CCC, CE, UL. RoHS |

| Size: | 125mm |

| Reduction Ratio: | 9 |

| Power of Servo Motor: | 1500W |

| Customization: |

Available

| Customized Request |

|---|

Can pulley gearboxes be customized for specific speed and torque requirements?

Yes, pulley gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer flexibility in designing and configuring pulley gearboxes to suit the specific needs of customers. Here’s a detailed explanation of how pulley gearboxes can be customized for specific speed and torque requirements:

Pulley Size and Configuration: The speed and torque output of a pulley gearbox can be adjusted by selecting the appropriate pulley sizes and configurations. The pulley diameter determines the speed ratio between the input and output shafts of the gearbox. By choosing different pulley sizes, the desired speed reduction or increase can be achieved. Additionally, adjusting the number of pulleys and their arrangement (e.g., single, double, or multiple stages) allows for further customization of the speed and torque characteristics of the gearbox.

Material Selection: The choice of materials for pulleys, belts, and other components in the gearbox can influence the torque capacity and durability. Different materials have varying strength and wear resistance properties, allowing manufacturers to select materials that can handle the specific torque requirements of the application. For higher torque applications, materials with greater strength and durability, such as reinforced belts or pulleys made of steel, may be chosen to ensure reliable performance.

Belt Type and Tension: The type of belt used in the pulley gearbox can impact the speed and torque characteristics. Manufacturers offer a range of belt types, such as V-belts, timing belts, or flat belts, each with different performance characteristics. For example, timing belts with toothed profiles provide precise synchronization and are suitable for applications requiring accurate positioning. Manufacturers can select the appropriate belt type and determine the optimal belt tension to achieve the desired speed and torque transfer while maintaining efficient power transmission.

Motor Selection: The motor driving the pulley gearbox plays a crucial role in determining the speed and torque capabilities of the system. Manufacturers consider the motor’s speed-torque curve, power rating, and other specifications to ensure compatibility with the pulley gearbox. By selecting motors with different characteristics, such as high torque at low speeds or high-speed capabilities, manufacturers can customize the overall system to meet specific speed and torque requirements.

Custom Gear Ratio: In some cases, manufacturers may offer the option to customize the gear ratio of the pulley gearbox by incorporating additional gears or pulley stages. This allows for fine-tuning of the speed and torque output to match the specific requirements of the application. By carefully calculating and designing the gear ratios, manufacturers can optimize the gearbox performance for the desired speed and torque range.

Application-Specific Design: Manufacturers may work closely with customers to understand their unique speed and torque requirements in specific applications. This collaboration enables the customization of pulley gearboxes to meet the exact needs of the application. Factors such as load conditions, duty cycles, ambient environment, and other operational considerations are taken into account to ensure the gearbox is designed and configured appropriately for the specific speed and torque requirements.

It is important to note that customized pulley gearboxes may require additional engineering analysis, such as stress calculations, dynamic simulations, or efficiency assessments, to ensure their performance meets the desired specifications. Collaborating with experienced manufacturers or engineering teams can help ensure the successful customization of pulley gearboxes for specific speed and torque requirements.

What maintenance practices are essential for prolonging the lifespan of pulley gearboxes?

Maintaining proper maintenance practices is crucial for prolonging the lifespan and ensuring the reliable operation of pulley gearboxes. Regular maintenance helps prevent premature wear, reduces the risk of breakdowns, and maximizes the efficiency of the gearbox. Here are some essential maintenance practices to consider for prolonging the lifespan of pulley gearboxes:

- Regular Inspection: Conduct regular visual inspections of the pulley gearboxes to identify any signs of wear, damage, or misalignment. Inspect the pulleys, belts or ropes, bearings, and other components for cracks, excessive wear, or loose connections. Detecting and addressing issues early can prevent further damage and extend the lifespan of the gearbox.

- Lubrication: Proper lubrication is vital for the smooth operation and longevity of pulley gearboxes. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Ensure that all lubrication points, such as bearings and shafts, are adequately lubricated. Regularly check the lubricant levels and replace or replenish the lubricant as needed.

- Belt or Rope Maintenance: If the pulley gearbox utilizes belts or ropes, pay attention to their condition and tension. Inspect the belts or ropes for signs of wear, fraying, or stretching. Adjust the tension according to the manufacturer’s guidelines to prevent slippage and ensure proper power transmission. Replace worn-out or damaged belts or ropes promptly to maintain optimal performance.

- Bearing Maintenance: Bearings play a critical role in the smooth operation of pulley gearboxes. Regularly inspect the bearings for signs of wear, overheating, or noise. Monitor the bearing temperature using appropriate tools and ensure it remains within the manufacturer’s recommended range. Clean the bearings if necessary and replace them when they reach the end of their service life.

- Alignment and Belt Tracking: Check the alignment of the pulleys periodically to ensure they are properly aligned. Misaligned pulleys can lead to increased wear, noise, and reduced efficiency. Adjust the alignment as needed to maintain optimal power transmission. Additionally, verify that the belts or ropes are tracking correctly on the pulleys to prevent unnecessary wear and belt slippage.

- Cleaning: Keep the pulley gearboxes clean and free from dirt, debris, and contaminants. Regularly remove any buildup or foreign particles that may affect the performance or cause damage. Use appropriate cleaning methods and avoid excessive moisture during cleaning to prevent corrosion or other adverse effects on the gearbox components.

- Temperature Monitoring: Monitor the operating temperature of the pulley gearboxes to ensure they remain within the recommended range. Excessive heat can accelerate wear and reduce the lifespan of the gearbox components. Install temperature sensors or use thermal imaging techniques to monitor the temperature and take corrective actions if needed, such as improving cooling or ventilation.

- Record Keeping: Maintain detailed records of maintenance activities, including inspections, lubrication schedules, repairs, and component replacements. This documentation helps track the maintenance history of the pulley gearboxes, identify recurring issues, and plan future maintenance tasks effectively. It also provides valuable information for troubleshooting and warranty claims, if applicable.

Following these maintenance practices and adhering to the manufacturer’s guidelines will help prolong the lifespan of pulley gearboxes. Regular inspections, proper lubrication, belt or rope maintenance, bearing maintenance, alignment checks, cleaning, temperature monitoring, and record keeping contribute to the reliable and efficient operation of the gearboxes over an extended period.

Are there variations in pulley gearbox designs for different load conditions?

Yes, there are variations in pulley gearbox designs to cater to different load conditions. The design of a pulley gearbox takes into account the specific load requirements, including the magnitude of the load, the nature of the load (constant or variable), and the duty cycle of the application. Here’s a detailed explanation of the variations in pulley gearbox designs for different load conditions:

- Heavy-Duty Load Conditions: For applications that involve heavy loads or high torque requirements, pulley gearboxes are designed with robust and durable components. These gearboxes are constructed using materials with high tensile strength and are engineered to withstand the stress and forces associated with heavy loads. Additionally, the pulley sizes and configurations are optimized to provide the necessary mechanical advantage and torque transfer capabilities.

- Light to Moderate Load Conditions: Pulley gearboxes designed for light to moderate load conditions may feature lighter and more compact designs. They are typically constructed using materials that offer a balance between strength and weight, optimizing the gearbox’s efficiency and performance for the specific load requirements. The pulley sizes and configurations are selected to provide the desired speed ratios and torque output while considering the load’s magnitude.

- Variable Load Conditions: In applications where the load conditions vary or are subject to fluctuations, pulley gearboxes may incorporate features to handle these variations. This can include adjustable pulley systems that allow for quick changes in speed ratios and torque output. The gearbox may also be designed to accommodate dynamic load conditions, with components engineered to absorb shocks and vibrations resulting from load variations.

- Continuous Duty Load Conditions: For applications that require continuous operation under load, pulley gearboxes are designed with considerations for heat dissipation and durability. They may incorporate cooling mechanisms such as fans or heat sinks to maintain optimal operating temperatures. The gearbox housing and components are designed to withstand prolonged operation and minimize wear and tear.

- Cyclic or Intermittent Load Conditions: Pulley gearboxes used in applications with cyclic or intermittent load conditions may be designed to handle the specific duty cycle. The gearbox may incorporate features such as enhanced lubrication systems to minimize friction and wear during start-stop cycles. The materials and construction may be optimized to withstand the repetitive loading and unloading cycles without compromising performance or reliability.

Overall, pulley gearbox designs can vary significantly depending on the load conditions they are intended to handle. The selection of materials, construction methods, pulley configurations, and additional features are all tailored to ensure optimal performance, durability, and efficiency for the specific load requirements of the application.

editor by CX 2024-01-29