Product Description

Overview

———————————————————————————————————————————————————————————————————————————————–

Quick Details

Gearing Arrangement: Worm Brand Name: CHINAMFG

Input Speed: 1400 rpm Output Speed: 14 rpm to 186 rpm

Rated Power: 0.06 ~ 4KW Output Torque: 2.6-479N.M

Color: Blue/Silver or on request Origin: ZHangZhoug, China (Mainland)

Warranty: 1 Year Application: Industry

———————————————————————————————————————————————————————————————————————————————–

Supply Ability

Supply Ability: 20000 Piece/Pieces per Month

Extra Service: OEM is welcome

QC System: ISO9001:2008

———————————————————————————————————————————————————————————————————————————————–

Packaging & Delivery

Package: Wooden box/Paper carton

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

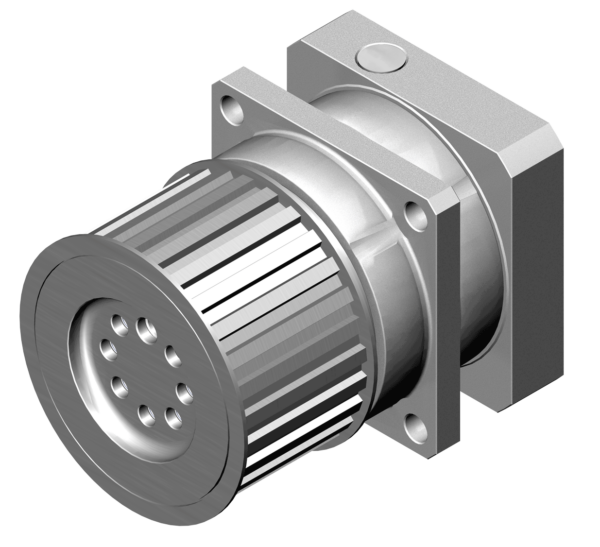

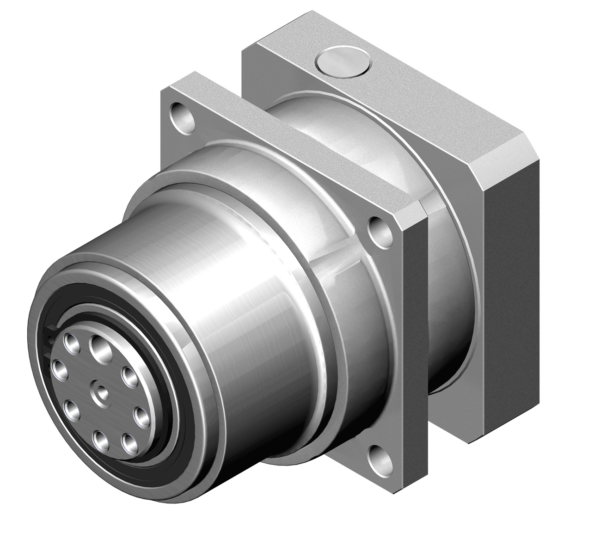

| TYPE | Worm Gear Speed Reducer/Worm Gearbox |

| MODEL | NMRV series size:571,030,040,050,063,075,090,110,130,150 |

| RATIO | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| COLOR | Blue(RAL5571)/Silver grey (RAL9571) or on your request |

| MATERIAL | Housing:Aluminum alloy |

| PACKING | Wooden box/Paper carton |

| BEARING | C&U |

| SEAL | SKF |

| WARRANTY | 1 Year |

| INPUT POWER | 0.09KM-15KM |

| USAGES | Foodstuffs, Ceramics, Packing, Chemicals, Pharmacy, Plastics, Paper-making, Machine-tools |

| IEC FLANGE | IEC standard flange or on request |

| LUBRICANT | Shell or Henry |

About CHINAMFG since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamp ing field since 1984. Our main product, NMRV worm gear speed reducer and series helical gearbox, XDR, XDF, XDK, XDS have reached the advanced technique index of the congeneric European and Janpanese produc ts. We offer standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders of non-standard products, such as gears, shafts, punching parts ect, according to customers’ drawings or sam ples.

Our company has complete set of equipment including CNC, lathes, milling machines, gear hobbing machine, g ear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding machines, drilling m achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing machines and s o on. We have advanced testing equipments as well.

Our company has established favorable cooperation relationships with sub-suppliers involving casting, raw material, heat treatment, surface finishing and so on.

The most advantage of the speed reducer is the technique of cobber clad, which can enhance the occlusal force between the bronze and core wheel.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Type: | Worm Reducer |

| Transport Package: | Shrink Packing, Carton Packing |

| Trademark: | OEM; EED |

| Customization: |

Available

| Customized Request |

|---|

Can you provide real-world examples of products that use pulley gearbox technology?

Pulley gearbox technology finds application in various industries and products where speed reduction, torque multiplication, and efficient power transmission are required. Here are some real-world examples of products that commonly use pulley gearbox technology:

Automotive Industry: Pulley gearboxes are widely used in automotive applications to transmit power and control rotational speed. One prominent example is the continuously variable transmission (CVT) system, which utilizes a pulley gearbox to provide seamless and efficient speed control. CVTs are found in many modern passenger vehicles, where they offer improved fuel efficiency by continuously adjusting the gear ratio to match the driving conditions. Pulley gearboxes are also employed in engine accessory drives, such as alternator drives, air conditioning compressor drives, and power steering systems.

Industrial Machinery: Pulley gearboxes are commonly utilized in various industrial machinery and equipment. Belt-driven machines, such as conveyor systems, packaging equipment, and material handling systems, often incorporate pulley gearboxes to transmit power and control speed. These gearboxes enable efficient power transfer and allow for easy speed adjustment to match specific application requirements. Additionally, pulley gearboxes are used in machine tools, textile machinery, printing presses, and many other industrial applications where precise speed control, torque multiplication, and energy efficiency are essential.

Exercise Equipment: Many types of exercise equipment, including treadmills, elliptical machines, and stationary bikes, utilize pulley gearboxes. These gearboxes are responsible for transmitting power from the motor to the moving components, such as the running belt or pedal assembly. By incorporating pulley gearboxes, exercise equipment manufacturers can provide users with adjustable speed settings and variable resistance levels, allowing for customized workouts and efficient energy utilization.

Home Appliances: Pulley gearboxes can be found in various home appliances where speed reduction and efficient power transmission are required. For example, washing machines often utilize pulley gearboxes to control the drum’s rotational speed during different wash cycles. Similarly, certain types of blenders and mixers use pulley gearboxes to achieve multiple speed settings for food preparation tasks. The gearboxes enable efficient power transfer and allow users to select the desired speed based on the specific application.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems commonly employ pulley gearboxes in their fan assemblies. These gearboxes enable speed control and ensure that the fans operate at the desired rotational speed for efficient air circulation. By adjusting the pulley sizes or gear ratios, the airflow can be optimized to match the cooling or heating demands of the space, resulting in energy savings and improved HVAC system performance.

Farming and Agricultural Equipment: Pulley gearboxes are utilized in various farming and agricultural equipment to transmit power and control rotational speed. Equipment such as combine harvesters, hay balers, and irrigation systems often incorporate pulley gearboxes to drive and control the speed of different components. These gearboxes enable efficient power transmission and help optimize the operation of agricultural machinery for improved productivity and reduced energy consumption.

Power Tools: Pulley gearboxes are also present in certain power tools to provide speed control and torque multiplication. Examples include bench grinders, drill presses, band saws, and woodworking equipment. By incorporating pulley gearboxes, power tool manufacturers can offer users the flexibility to adjust the speed and optimize the tool’s performance for various applications, while ensuring efficient power transfer and reduced power consumption.

Entertainment Industry: In the entertainment industry, pulley gearboxes are utilized in various equipment and devices. Examples include stage machinery for theater productions, where pulley gearboxes are used to control the movement of curtains, scenery, and other stage elements. Pulley gearboxes are also found in amusement park rides, enabling precise speed control and ensuring the safety and enjoyment of the riders.

These are just a few examples of the wide range of products and industries that utilize pulley gearbox technology. The versatility and efficiency of pulley gearboxes make them a valuable component in numerous applications where power transmission, speed control, and energy efficiency are essential.

How do pulley gearboxes ensure efficient power transmission and speed regulation?

Pulley gearboxes employ various mechanisms and design features to ensure efficient power transmission and speed regulation. These elements work together to optimize the transfer of power and enable precise control over the rotational speed. Here’s a detailed explanation of how pulley gearboxes achieve efficient power transmission and speed regulation:

- Pulley Size and Ratio Selection: Pulley gearboxes utilize different pulley sizes and ratios to achieve the desired speed regulation and power transmission efficiency. By selecting appropriate pulley sizes, the gear ratio can be adjusted to match the specific requirements of the application. This ensures that the power is effectively transferred from the driving pulley to the driven pulley, allowing for efficient power transmission.

- Mechanical Advantage: Pulley gearboxes leverage the principle of mechanical advantage to enhance power transmission efficiency. The use of different-sized pulleys creates a mechanical advantage that amplifies the torque output. Larger driving pulleys and smaller driven pulleys result in a higher mechanical advantage, allowing for greater torque transfer. This mechanical advantage ensures efficient power transmission, especially when dealing with varying load conditions.

- Tension and Friction Control: Proper tension and friction control are vital for efficient power transmission in pulley gearboxes. The tension in the belts or ropes connecting the pulleys is adjusted to ensure a firm grip and prevent slippage. Adequate tension helps maximize power transfer efficiency. The friction between the belts or ropes and the pulleys is also optimized to facilitate smooth power transmission. The right amount of friction ensures effective torque transfer while minimizing energy losses.

- Material Selection: The choice of materials for the pulleys, belts or ropes, and other gearbox components plays a crucial role in efficient power transmission. High-quality materials with low friction coefficients and high tensile strength are used to reduce energy losses and minimize wear. The materials are selected based on the specific application requirements to ensure optimal performance and durability.

- Alignment and Belt Tracking: Proper alignment of the pulleys and accurate belt tracking contribute to efficient power transmission and speed regulation. Misalignment and incorrect belt tracking can lead to increased friction, energy losses, and premature wear. Pulley gearboxes are designed with features that facilitate easy alignment adjustment and belt tracking to maintain optimal power transmission efficiency.

- Efficiency Optimization: Pulley gearboxes undergo design optimizations to maximize power transmission efficiency. This includes reducing frictional losses through the use of high-quality bearings, improved lubrication systems, and efficient sealing mechanisms. Minimizing internal losses within the gearbox components helps ensure efficient power transmission and speed regulation.

- Speed Control Mechanisms: Pulley gearboxes often incorporate speed control mechanisms to regulate the rotational speed of the driven pulley. These mechanisms can include adjustable pulley systems, variable speed drives, or additional gear stages. By providing the ability to adjust the speed ratio, pulley gearboxes enable precise speed regulation and accommodate varying operational requirements.

Overall, pulley gearboxes ensure efficient power transmission and speed regulation through a combination of pulley size and ratio selection, mechanical advantage, tension and friction control, material selection, alignment and belt tracking, efficiency optimization, and speed control mechanisms. These design elements work together to optimize power transfer, minimize energy losses, and provide reliable speed regulation in a wide range of applications.

What benefits do pulley gearboxes offer in various industrial applications?

Pulley gearboxes provide numerous benefits in various industrial applications. They offer advantages that contribute to efficient power transmission, speed control, versatility, and reliability. Here’s a detailed explanation of the benefits that pulley gearboxes offer in industrial applications:

- Power Transmission: Pulley gearboxes excel at power transmission between rotating shafts. They efficiently transfer rotational force and torque through the use of belts or ropes and pulleys. The friction between the belts or ropes and the pulleys ensures reliable power transmission without slippage, enabling the transfer of power from the driving pulley to the driven pulley.

- Speed Control: Pulley gearboxes allow for precise speed control in industrial applications. By utilizing pulleys of different sizes, the rotational speed can be adjusted according to specific operational requirements. The adjustability of pulley gearboxes facilitates speed conversion, enabling the system to operate at the desired speed while maintaining efficient power transmission.

- Flexibility and Adaptability: Pulley gearboxes offer flexibility and adaptability in industrial applications. They can be easily configured with different pulley sizes and arrangements to achieve specific speed and torque ratios. This versatility allows pulley gearboxes to adapt to varying load conditions, operational requirements, and system constraints, making them suitable for a wide range of industrial applications.

- Compact Size: Pulley gearboxes can be designed in compact sizes, making them ideal for industrial applications where space is limited. Their compact form factor allows for easy integration into machinery and equipment without occupying excessive space, optimizing the layout and efficiency of industrial systems.

- Cost-Effectiveness: Pulley gearboxes offer a cost-effective solution for power transmission and speed control in industrial applications. They are relatively simple in design and construction, resulting in lower manufacturing costs compared to more complex gearbox alternatives. The cost-effectiveness of pulley gearboxes makes them an attractive choice for industrial applications where budget constraints are a consideration.

- Reliability: Pulley gearboxes are known for their reliability in industrial settings. The use of belts or ropes in the pulley system helps absorb shocks and vibrations, reducing the risk of component failure and ensuring smooth operation. The frictional power transmission mechanism of pulley gearboxes provides robust and dependable performance, enhancing the overall reliability and longevity of industrial systems.

- Wide Range of Applications: Pulley gearboxes find applications in various industrial sectors. They are utilized in conveyor systems, manufacturing equipment, material handling machinery, agricultural machinery, automotive accessories, fitness equipment, and more. The versatility of pulley gearboxes makes them suitable for diverse industrial applications where power transmission, speed control, and adaptability are essential.

The benefits offered by pulley gearboxes in industrial applications, including efficient power transmission, precise speed control, flexibility, compact size, cost-effectiveness, reliability, and versatility, make them a popular choice for engineers and designers. By leveraging the advantages of pulley gearboxes, industrial systems can achieve optimized performance, improved productivity, and enhanced operational efficiency.

editor by CX 2024-03-30