Product Description

Our Agricultural Machinery Gearbox has many items for your choosing and we can produce as per your drawing or sample to meet your special request

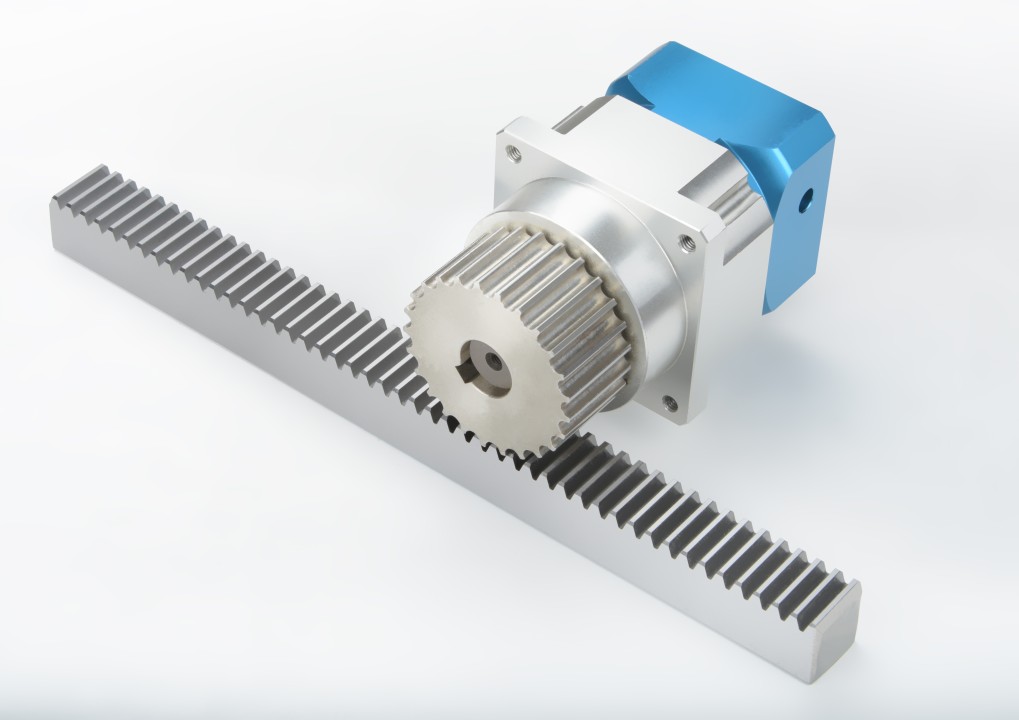

1. Large output torque

2. Safe, reliable, economical and durable

3. Stable transmission, quiet operation

4. High carrying ability

5. High modularization design, may equip with various outer power input conveniently. Same machine type may equip with various power motor. It is easy to realize the combination and junction between every machine type

6. Transmission ratio: Fine division, wide scope. The combined machine type may form very large transmission ratio, i. E. Output very low rotary speed.

7. Form of installation: The position to be installed is not limited.

8. High strength, compact the box body of high strength cast iron, gear and gear shaft adapts the gas carbonization, quenching and fine grinding process, therefore the bearing capacity of unit volume is high.

9. Long life: Under the condition of correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life if main parts speed reducer(except wearing parts)should not be less than 20000 hours. The wearing parts include lubricating oil, oil seal and bearing.

10. Low noise: Because main parts of speed reducer are processed, and tested critically, therefore the noise of speed reducer is low.

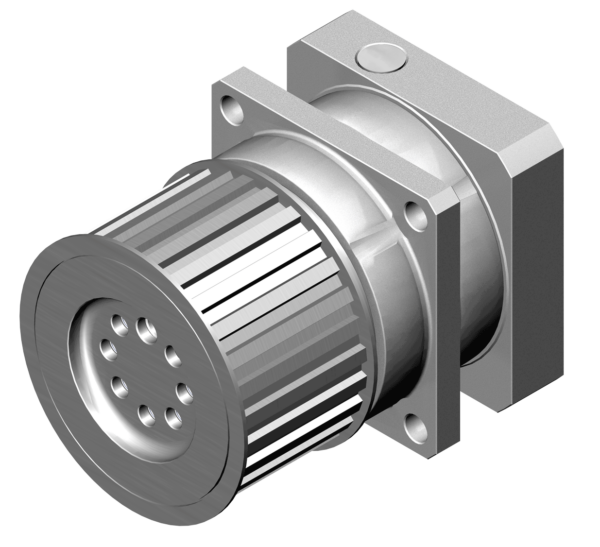

11. Parallel axis-bevel wheel speed-down motor.

See the below features:

Size: 40mm—160mm

Reduction ratio: 3 — 512

Torque transmission: 5 Nm — 8 95 Nm

Precision backlash: ≤ 5arcmin

Running noise: 51 70 dB (A)

You are welcome to send us detail enquiry by e-mail or fax.

We can also supply Gearbox, agricultural gearbox, planetary gearbox, worm gearbox, CHINAMFG gearbox, marine gearbox, gearbox, reduction gearbox, transmission gearbox, gearbox, mower gearbox, rotary cutter gearbox, small transmission gearbox, gearbox for conveyor, bevel gearbox, helical gearbox, swing gearbox, variable speed gearbox, differential gearbox, small planetary gearbox, reducer gearbox, tiller gearbox, pto gearbox, gearbox reducer, hollow shaft gearbox, speed reduction gearbox, industrial gearbox, planetary reduction gearbox, lawn mower gearbox, rotary tiller gearbox, gearbox transmission, worm reduction gearbox, aluminum gearbox, forklift gearbox, nmrv 075 worm gearbox, nmrv030 worm gearbox, shaft mounted gearbox, nmrv 050 worm gearbox, gearbox for agricultural machinery, power tiller gearbox, manual worm gearbox, spiral bevel gearbox, nmrv gearbox, worm wheel gearbox, reduce speed gearbox, industrial transmission gearbox, worm reducer gearbox, gearbox rpm reducer, helical gearbox reducer, wheel planetary gearbox, nmrv040 worm gearbox, worm gearbox reducer, nmrv worm gearbox, aluminium worm gearbox, gearbox reduction, rv series worm gearbox, worm speed gearbox, nmrv050 worm gearbox, gear reducer, worm gear reducer, helical gear reducer, gear speed reducer, worm gear speed reducer, shaft mounted gear reducer, planetary gear reducer, helical gear speed reducer, worm CHINAMFG reducer, speed gear reducer, bevel gear reducer, planetary gear speed reducer, spur gear reducer, aluminum worm gear reduce, nmrv worm gear reducers, helical-worm gear reducer, helical bevel gear reducers, high speed gear reducer, gear speed reducers, industrial gear reducer, high torque gear reducers

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Reducer |

|---|---|

| Hardness: | Hardened |

| Type: | Bevel Gear |

| Manipulate Way: | Semi-Automatic Manipulation |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the durability of pulley gearboxes in industrial environments?

Manufacturers take several measures to ensure the durability of pulley gearboxes in industrial environments. These measures involve careful design, material selection, manufacturing processes, and quality control. Here’s a detailed explanation of how manufacturers ensure the durability of pulley gearboxes:

Robust Design: Manufacturers employ robust design practices to ensure that pulley gearboxes can withstand the demands of industrial environments. The gearbox is designed to handle the anticipated loads, torque, and operating conditions specific to the intended application. Factors such as appropriate housing design, proper alignment of pulley shafts, and reinforcement in critical areas are taken into account during the design phase to enhance the durability and reliability of the gearbox.

Material Selection: Careful selection of materials is crucial for ensuring the durability of pulley gearboxes. Manufacturers choose materials that exhibit high strength, wear resistance, and corrosion resistance to withstand the harsh operating conditions in industrial environments. Components such as pulleys, shafts, bearings, and housings are typically made from materials such as steel alloys, cast iron, or aluminum, depending on the specific application requirements and environmental factors.

Quality Manufacturing Processes: Manufacturers employ precise and quality manufacturing processes to produce pulley gearboxes that meet stringent standards. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, ensure accurate dimensions and proper fitment of components. The gearbox components are manufactured with tight tolerances to ensure smooth operation and minimize friction. Additionally, manufacturers follow industry best practices and quality control measures to ensure consistent and reliable production of gearboxes.

Proper Lubrication: Lubrication is critical for the smooth operation and durability of pulley gearboxes. Manufacturers specify appropriate lubricants for the gearbox based on factors such as load, speed, temperature, and operating environment. Adequate lubrication reduces friction, minimizes wear on components, dissipates heat, and helps prevent corrosion. Manufacturers may provide guidelines for the recommended lubrication schedule and type of lubricant to be used, and users are advised to follow these recommendations for optimal gearbox performance and durability.

Testing and Validation: Manufacturers subject pulley gearboxes to rigorous testing and validation procedures to ensure their durability. These tests may include load testing, endurance testing, temperature testing, and performance evaluation under various operating conditions. Testing helps identify potential weaknesses or design flaws, allowing manufacturers to make necessary improvements to enhance the durability and reliability of the gearboxes. Compliance with industry standards and regulations is also an important aspect of the testing and validation process.

Environmental Protection: In industrial environments, pulley gearboxes may be exposed to dust, debris, moisture, or other contaminants that can impact their durability. Manufacturers address this by incorporating protective measures into the gearbox design. This may include sealing mechanisms to prevent ingress of contaminants, such as dust seals or labyrinth seals, as well as the use of coatings or surface treatments to enhance corrosion resistance. These protective measures help extend the lifespan of the gearbox and maintain its performance in challenging environments.

User Education and Support: Manufacturers often provide user manuals, technical documentation, and support to ensure that users understand how to operate and maintain the pulley gearbox properly. This includes information on recommended maintenance practices, lubrication procedures, and troubleshooting guidelines. By educating users about the gearbox’s operational requirements, manufacturers help optimize its durability and minimize the risk of premature failure.

By implementing these measures, manufacturers aim to ensure that pulley gearboxes can withstand the demanding conditions of industrial environments and provide long-lasting, reliable performance.

How do pulley gearboxes ensure efficient power transmission and speed regulation?

Pulley gearboxes employ various mechanisms and design features to ensure efficient power transmission and speed regulation. These elements work together to optimize the transfer of power and enable precise control over the rotational speed. Here’s a detailed explanation of how pulley gearboxes achieve efficient power transmission and speed regulation:

- Pulley Size and Ratio Selection: Pulley gearboxes utilize different pulley sizes and ratios to achieve the desired speed regulation and power transmission efficiency. By selecting appropriate pulley sizes, the gear ratio can be adjusted to match the specific requirements of the application. This ensures that the power is effectively transferred from the driving pulley to the driven pulley, allowing for efficient power transmission.

- Mechanical Advantage: Pulley gearboxes leverage the principle of mechanical advantage to enhance power transmission efficiency. The use of different-sized pulleys creates a mechanical advantage that amplifies the torque output. Larger driving pulleys and smaller driven pulleys result in a higher mechanical advantage, allowing for greater torque transfer. This mechanical advantage ensures efficient power transmission, especially when dealing with varying load conditions.

- Tension and Friction Control: Proper tension and friction control are vital for efficient power transmission in pulley gearboxes. The tension in the belts or ropes connecting the pulleys is adjusted to ensure a firm grip and prevent slippage. Adequate tension helps maximize power transfer efficiency. The friction between the belts or ropes and the pulleys is also optimized to facilitate smooth power transmission. The right amount of friction ensures effective torque transfer while minimizing energy losses.

- Material Selection: The choice of materials for the pulleys, belts or ropes, and other gearbox components plays a crucial role in efficient power transmission. High-quality materials with low friction coefficients and high tensile strength are used to reduce energy losses and minimize wear. The materials are selected based on the specific application requirements to ensure optimal performance and durability.

- Alignment and Belt Tracking: Proper alignment of the pulleys and accurate belt tracking contribute to efficient power transmission and speed regulation. Misalignment and incorrect belt tracking can lead to increased friction, energy losses, and premature wear. Pulley gearboxes are designed with features that facilitate easy alignment adjustment and belt tracking to maintain optimal power transmission efficiency.

- Efficiency Optimization: Pulley gearboxes undergo design optimizations to maximize power transmission efficiency. This includes reducing frictional losses through the use of high-quality bearings, improved lubrication systems, and efficient sealing mechanisms. Minimizing internal losses within the gearbox components helps ensure efficient power transmission and speed regulation.

- Speed Control Mechanisms: Pulley gearboxes often incorporate speed control mechanisms to regulate the rotational speed of the driven pulley. These mechanisms can include adjustable pulley systems, variable speed drives, or additional gear stages. By providing the ability to adjust the speed ratio, pulley gearboxes enable precise speed regulation and accommodate varying operational requirements.

Overall, pulley gearboxes ensure efficient power transmission and speed regulation through a combination of pulley size and ratio selection, mechanical advantage, tension and friction control, material selection, alignment and belt tracking, efficiency optimization, and speed control mechanisms. These design elements work together to optimize power transfer, minimize energy losses, and provide reliable speed regulation in a wide range of applications.

Are there variations in pulley gearbox designs for different load conditions?

Yes, there are variations in pulley gearbox designs to cater to different load conditions. The design of a pulley gearbox takes into account the specific load requirements, including the magnitude of the load, the nature of the load (constant or variable), and the duty cycle of the application. Here’s a detailed explanation of the variations in pulley gearbox designs for different load conditions:

- Heavy-Duty Load Conditions: For applications that involve heavy loads or high torque requirements, pulley gearboxes are designed with robust and durable components. These gearboxes are constructed using materials with high tensile strength and are engineered to withstand the stress and forces associated with heavy loads. Additionally, the pulley sizes and configurations are optimized to provide the necessary mechanical advantage and torque transfer capabilities.

- Light to Moderate Load Conditions: Pulley gearboxes designed for light to moderate load conditions may feature lighter and more compact designs. They are typically constructed using materials that offer a balance between strength and weight, optimizing the gearbox’s efficiency and performance for the specific load requirements. The pulley sizes and configurations are selected to provide the desired speed ratios and torque output while considering the load’s magnitude.

- Variable Load Conditions: In applications where the load conditions vary or are subject to fluctuations, pulley gearboxes may incorporate features to handle these variations. This can include adjustable pulley systems that allow for quick changes in speed ratios and torque output. The gearbox may also be designed to accommodate dynamic load conditions, with components engineered to absorb shocks and vibrations resulting from load variations.

- Continuous Duty Load Conditions: For applications that require continuous operation under load, pulley gearboxes are designed with considerations for heat dissipation and durability. They may incorporate cooling mechanisms such as fans or heat sinks to maintain optimal operating temperatures. The gearbox housing and components are designed to withstand prolonged operation and minimize wear and tear.

- Cyclic or Intermittent Load Conditions: Pulley gearboxes used in applications with cyclic or intermittent load conditions may be designed to handle the specific duty cycle. The gearbox may incorporate features such as enhanced lubrication systems to minimize friction and wear during start-stop cycles. The materials and construction may be optimized to withstand the repetitive loading and unloading cycles without compromising performance or reliability.

Overall, pulley gearbox designs can vary significantly depending on the load conditions they are intended to handle. The selection of materials, construction methods, pulley configurations, and additional features are all tailored to ensure optimal performance, durability, and efficiency for the specific load requirements of the application.

editor by CX 2024-04-24