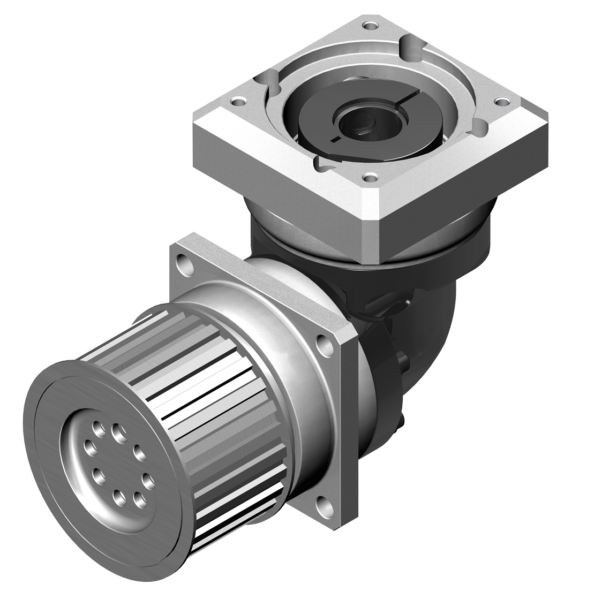

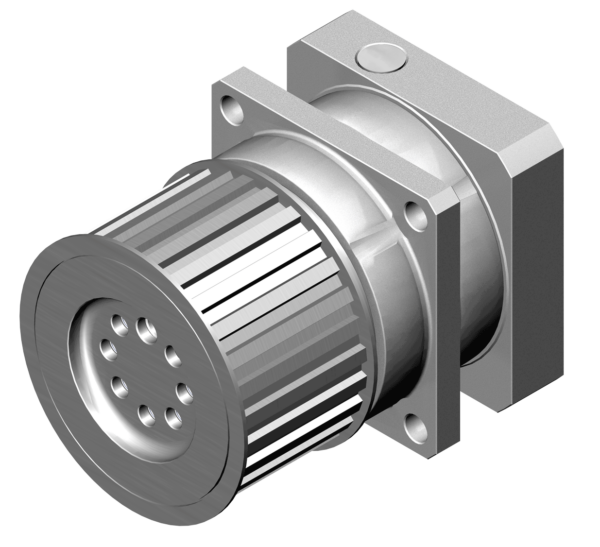

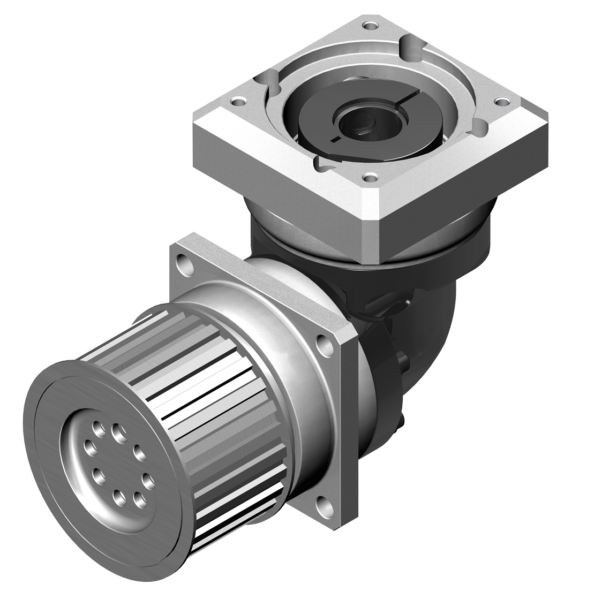

Product Description

Smr Smsr Parallel Hollow Axis Shaft Mounted Reductor Backstop Manufacturer Reduction Gear Unit Box Gearbox

Features

1. High strength of housing, gears, and shafts, sturdy and durable.

2. Metric output shaft bore diameters (Standard and Optional).

3. Optional backstop to prevent back driving. The backstop is not recommended for the gear ratio of 5.

4. Double lips skeleton oil seal combines the functions of seal and dust-proof.

5. Widely used in belt conveyor and pulley drive systems.

Product Photos

Product Description

| Gearing Arrangement | Parallel shaft mounted gearbox |

| Output Torque | 256-7449N.m |

| Input Speed | 1400rpm |

| Output Speed | 100 ~ 400RPM |

FAQ

Q: Can you make the shaft mounted gearbox with customization?

A: Yes, we can customize per your request, like flange, shaft, configuration, material, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What’s your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technology support?

A: Yes. Our company has a design and development team, we can provide technology support if you

need.

Q: How do you ship to us?

A: It is available by air, sea, or train.

Q: How do I pay the money?

A: T/T and L/C are preferred, with a different currency, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: > 1st confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Belt Conveyor and Pulley Drive System |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Parallel Shaft |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | Order Sample Blue or Grey

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do pulley gearboxes contribute to energy efficiency and reduced power consumption?

Pulley gearboxes play a significant role in improving energy efficiency and reducing power consumption in various mechanical systems. They achieve this through several mechanisms and advantages inherent to their design and operation. Here’s a detailed explanation of how pulley gearboxes contribute to energy efficiency and reduced power consumption:

Speed Reduction: One of the primary functions of pulley gearboxes is to reduce the rotational speed of the input shaft while increasing the torque at the output shaft. This speed reduction allows the driven equipment to operate at a lower speed without sacrificing the required torque. By slowing down the rotational speed, pulley gearboxes enable the use of smaller and more efficient motors or engines, which consume less power compared to their high-speed counterparts. This speed reduction mechanism contributes to energy savings in applications where high speeds are not necessary.

Torque Multiplication: Pulley gearboxes also provide torque multiplication, allowing higher torque to be delivered at the output shaft compared to the input shaft. This torque multiplication capability enables the use of smaller and more efficient motors or engines that can operate at lower torque levels. By reducing the torque demand on the driving source, such as an electric motor, pulley gearboxes help optimize power consumption and improve overall energy efficiency.

Efficient Power Transfer: Pulley gearboxes employ belts or chains to transmit power between the input and output shafts. These flexible power transmission elements have the advantage of dampening vibrations and reducing noise compared to direct gear-to-gear mechanisms. The use of belts or chains also helps to mitigate shock loads and minimize backlash, resulting in smoother power transmission. The reduced mechanical losses and improved power transfer efficiency contribute to energy savings and increased overall system efficiency.

Variable Speed Control: Pulley gearboxes, especially those with adjustable pulley sizes or multiple stages, offer the advantage of variable speed control. By adjusting the position of the belt on the pulleys or changing the gear ratio, the output speed can be easily modified to match the requirements of the driven equipment or process. This variable speed control capability allows for optimal operation in different load conditions, avoiding unnecessary energy consumption at higher speeds when lower speeds would suffice. By adapting the speed to the specific needs of the application, pulley gearboxes contribute to energy efficiency and reduced power consumption.

Load Matching: Pulley gearboxes facilitate load matching, which means optimizing the speed and torque characteristics of the output shaft to match the requirements of the driven load. By selecting the appropriate pulley sizes or gear ratios, the pulley gearbox can be tailored to provide the right combination of speed and torque for the specific application. This load matching capability ensures that the driven equipment operates at its most efficient point, minimizing energy losses and reducing power consumption.

Power Loss Minimization: Pulley gearboxes are designed to minimize power losses resulting from friction and mechanical inefficiencies. Manufacturers employ various techniques to improve the efficiency of pulley gearboxes, such as using high-quality bearings, optimizing gear tooth profiles, reducing internal clearances, and selecting low-friction materials. These design considerations help minimize power losses and maximize energy transfer efficiency, thereby reducing power consumption.

System Optimization: Pulley gearboxes are often integrated into larger mechanical systems where the overall system efficiency is critical. By providing the necessary speed reduction, torque multiplication, and load matching capabilities, pulley gearboxes enable the optimization of the entire system. This optimization may involve selecting the most efficient motor, engine, or prime mover, as well as optimizing the sizing and selection of other components in the system. By contributing to system efficiency, pulley gearboxes play a vital role in reducing overall power consumption.

It is important to note that the energy efficiency and power consumption of pulley gearboxes depend not only on their design and operation but also on other factors such as the application, load conditions, maintenance, and the overall system design. Collaborating with experienced engineers and manufacturers can help ensure the proper selection, sizing, and utilization of pulley gearboxes to achieve the desired energy efficiency and power savings.

How do pulley gearboxes ensure efficient power transmission and speed regulation?

Pulley gearboxes employ various mechanisms and design features to ensure efficient power transmission and speed regulation. These elements work together to optimize the transfer of power and enable precise control over the rotational speed. Here’s a detailed explanation of how pulley gearboxes achieve efficient power transmission and speed regulation:

- Pulley Size and Ratio Selection: Pulley gearboxes utilize different pulley sizes and ratios to achieve the desired speed regulation and power transmission efficiency. By selecting appropriate pulley sizes, the gear ratio can be adjusted to match the specific requirements of the application. This ensures that the power is effectively transferred from the driving pulley to the driven pulley, allowing for efficient power transmission.

- Mechanical Advantage: Pulley gearboxes leverage the principle of mechanical advantage to enhance power transmission efficiency. The use of different-sized pulleys creates a mechanical advantage that amplifies the torque output. Larger driving pulleys and smaller driven pulleys result in a higher mechanical advantage, allowing for greater torque transfer. This mechanical advantage ensures efficient power transmission, especially when dealing with varying load conditions.

- Tension and Friction Control: Proper tension and friction control are vital for efficient power transmission in pulley gearboxes. The tension in the belts or ropes connecting the pulleys is adjusted to ensure a firm grip and prevent slippage. Adequate tension helps maximize power transfer efficiency. The friction between the belts or ropes and the pulleys is also optimized to facilitate smooth power transmission. The right amount of friction ensures effective torque transfer while minimizing energy losses.

- Material Selection: The choice of materials for the pulleys, belts or ropes, and other gearbox components plays a crucial role in efficient power transmission. High-quality materials with low friction coefficients and high tensile strength are used to reduce energy losses and minimize wear. The materials are selected based on the specific application requirements to ensure optimal performance and durability.

- Alignment and Belt Tracking: Proper alignment of the pulleys and accurate belt tracking contribute to efficient power transmission and speed regulation. Misalignment and incorrect belt tracking can lead to increased friction, energy losses, and premature wear. Pulley gearboxes are designed with features that facilitate easy alignment adjustment and belt tracking to maintain optimal power transmission efficiency.

- Efficiency Optimization: Pulley gearboxes undergo design optimizations to maximize power transmission efficiency. This includes reducing frictional losses through the use of high-quality bearings, improved lubrication systems, and efficient sealing mechanisms. Minimizing internal losses within the gearbox components helps ensure efficient power transmission and speed regulation.

- Speed Control Mechanisms: Pulley gearboxes often incorporate speed control mechanisms to regulate the rotational speed of the driven pulley. These mechanisms can include adjustable pulley systems, variable speed drives, or additional gear stages. By providing the ability to adjust the speed ratio, pulley gearboxes enable precise speed regulation and accommodate varying operational requirements.

Overall, pulley gearboxes ensure efficient power transmission and speed regulation through a combination of pulley size and ratio selection, mechanical advantage, tension and friction control, material selection, alignment and belt tracking, efficiency optimization, and speed control mechanisms. These design elements work together to optimize power transfer, minimize energy losses, and provide reliable speed regulation in a wide range of applications.

Can you explain the different types of pulley gearboxes and their specific functions?

There are several different types of pulley gearboxes, each with its specific functions and applications. These variations in design and configuration allow pulley gearboxes to cater to diverse requirements in power transmission and speed control. Here’s an explanation of the different types of pulley gearboxes and their specific functions:

- Fixed Ratio Pulley Gearbox: This type of pulley gearbox consists of two pulleys of different sizes that are fixed to their respective shafts. The driving pulley and the driven pulley are connected by a belt or rope. The fixed ratio pulley gearbox is primarily used for speed conversion, where the rotational speed is either increased or decreased while maintaining a constant ratio between the input and output shafts. It is commonly employed in applications where a specific speed conversion is required, such as in conveyor systems or certain types of machinery.

- Variable Ratio Pulley Gearbox: Also known as a variable speed pulley gearbox or a stepless transmission, this type of gearbox allows for continuous and stepless variation of the speed ratio between the input and output shafts. It typically consists of two conical pulleys connected by a V-belt or a similar mechanism. By adjusting the distance between the two pulleys, the effective diameter of the pulleys changes, resulting in variable speed ratios. Variable ratio pulley gearboxes are commonly used in applications that require smooth and precise speed control, such as in automotive transmissions, industrial machinery, and exercise equipment.

- Compound Pulley Gearbox: A compound pulley gearbox utilizes multiple pulleys arranged in a series or parallel configuration to achieve complex speed and torque conversions. It involves intermediate pulleys and idler pulleys to redirect the belt or rope path. Compound pulley gearboxes offer versatility in speed control and power transmission, allowing for a wide range of speed and torque ratios. They find applications in various industrial systems, including complex machinery, assembly lines, and material handling equipment.

- Reversible Pulley Gearbox: This type of pulley gearbox is designed to provide bidirectional power transmission. It typically consists of two pulleys of the same size connected by a belt or rope. By shifting the belt or rope to different positions on the pulleys, the direction of power transmission can be reversed. Reversible pulley gearboxes are commonly used in applications where the ability to change the direction of rotation is required, such as in winches, hoists, and certain types of machinery.

- Step-Up and Step-Down Pulley Gearbox: Step-up and step-down pulley gearboxes are designed to either increase or decrease the rotational speed and torque between the input and output shafts. Step-up pulley gearboxes have a smaller driving pulley and a larger driven pulley, resulting in higher output speed and lower torque. They are used in applications where high-speed operation is required, such as in certain types of machine tools. Step-down pulley gearboxes have a larger driving pulley and a smaller driven pulley, resulting in lower output speed and higher torque. They are commonly used in applications that require high torque, such as in heavy-duty machinery and equipment.

The specific functions of pulley gearboxes are determined by their design, configuration, and the requirements of the application. By selecting the appropriate type of pulley gearbox, engineers and designers can achieve the desired speed control, power transmission, and adaptability for a wide range of industrial applications.

editor by CX 2024-01-25