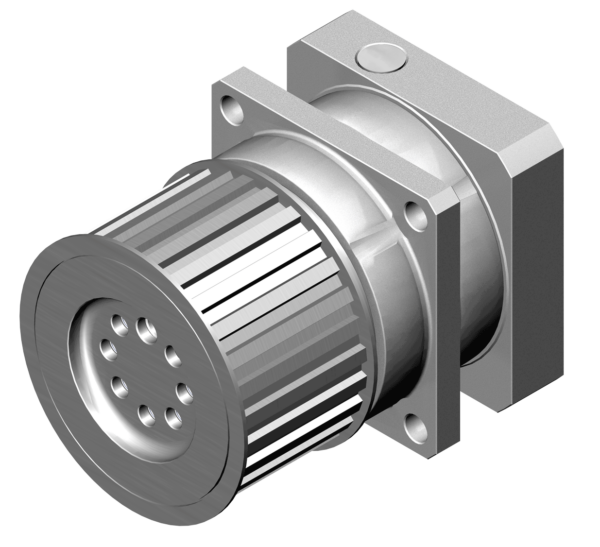

Product Description

Precision planetary gear reducer is a new-generation of product developed by our company, with a compromise of advanced technology both at home and abroad, its main features are as follows:

1. Low noise: under 65db.

2. Low backlash: within 3 arcmin.

3. High efficiency: 97% for 1 stage, 94% for 2 stages.

4. High input speed: Rated input speed 3000rpm, max input speed 6000 rpm.

5. High output torque: higher torque output than that of conventional planetary gear reducer.

6. High stability hardening,which extends gear service life and maintain high accuracy as new after a long period of operation.

Precicion planetary gear reducer is widely used in the following fields:

1. Aerospace, military industries.

2. Medical health, electronic information industries.

3. Industrial robots, productin automation, CNC machine tool manufacturing industries.

4. Motor,textile,printing,food,metallurgical,envrironment protection engineering, warehouse logistics industries.

About Xingda since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamp

ing field since 1984. Our main product, NMRV worm gear speed reducer and series helical gearbox, XDR,

XDF, XDK, XDShave reached the advanced technique index of the congeneric European and Janpanese produc

ts, We offer standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders

of non-standard products, such as gears, shafts, punching parts ect, according to customers’ Drawings or sam-

ples.

Our company has complete set of equipment including CNC, lathes, milling machines, gear hobbing machine, g-

ear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding machines, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing machines and s-

o on. We have advanced testing equipments also.

Our company has established favorable cooperation relationships with sub-suppliers involving casting, raw mat-

erial, heat treatment, surface finishing and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Step: | Double-Step |

| Type: | Planetary Gear Reducer |

| Samples: |

US$ 230/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can pulley gearboxes be customized for specific speed and torque requirements?

Yes, pulley gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer flexibility in designing and configuring pulley gearboxes to suit the specific needs of customers. Here’s a detailed explanation of how pulley gearboxes can be customized for specific speed and torque requirements:

Pulley Size and Configuration: The speed and torque output of a pulley gearbox can be adjusted by selecting the appropriate pulley sizes and configurations. The pulley diameter determines the speed ratio between the input and output shafts of the gearbox. By choosing different pulley sizes, the desired speed reduction or increase can be achieved. Additionally, adjusting the number of pulleys and their arrangement (e.g., single, double, or multiple stages) allows for further customization of the speed and torque characteristics of the gearbox.

Material Selection: The choice of materials for pulleys, belts, and other components in the gearbox can influence the torque capacity and durability. Different materials have varying strength and wear resistance properties, allowing manufacturers to select materials that can handle the specific torque requirements of the application. For higher torque applications, materials with greater strength and durability, such as reinforced belts or pulleys made of steel, may be chosen to ensure reliable performance.

Belt Type and Tension: The type of belt used in the pulley gearbox can impact the speed and torque characteristics. Manufacturers offer a range of belt types, such as V-belts, timing belts, or flat belts, each with different performance characteristics. For example, timing belts with toothed profiles provide precise synchronization and are suitable for applications requiring accurate positioning. Manufacturers can select the appropriate belt type and determine the optimal belt tension to achieve the desired speed and torque transfer while maintaining efficient power transmission.

Motor Selection: The motor driving the pulley gearbox plays a crucial role in determining the speed and torque capabilities of the system. Manufacturers consider the motor’s speed-torque curve, power rating, and other specifications to ensure compatibility with the pulley gearbox. By selecting motors with different characteristics, such as high torque at low speeds or high-speed capabilities, manufacturers can customize the overall system to meet specific speed and torque requirements.

Custom Gear Ratio: In some cases, manufacturers may offer the option to customize the gear ratio of the pulley gearbox by incorporating additional gears or pulley stages. This allows for fine-tuning of the speed and torque output to match the specific requirements of the application. By carefully calculating and designing the gear ratios, manufacturers can optimize the gearbox performance for the desired speed and torque range.

Application-Specific Design: Manufacturers may work closely with customers to understand their unique speed and torque requirements in specific applications. This collaboration enables the customization of pulley gearboxes to meet the exact needs of the application. Factors such as load conditions, duty cycles, ambient environment, and other operational considerations are taken into account to ensure the gearbox is designed and configured appropriately for the specific speed and torque requirements.

It is important to note that customized pulley gearboxes may require additional engineering analysis, such as stress calculations, dynamic simulations, or efficiency assessments, to ensure their performance meets the desired specifications. Collaborating with experienced manufacturers or engineering teams can help ensure the successful customization of pulley gearboxes for specific speed and torque requirements.

How do pulley gearboxes handle variations in load and torque during operation?

Pulley gearboxes are designed to handle variations in load and torque during operation by utilizing the mechanical advantage provided by the pulley system and adjusting the pulley ratios. This flexibility allows pulley gearboxes to adapt to changing conditions and maintain consistent performance. Here’s a detailed explanation of how pulley gearboxes handle load and torque variations:

Mechanical Advantage: Pulley gearboxes utilize the principle of mechanical advantage to handle variations in load and torque. The different sizes of the driving and driven pulleys create a mechanical advantage that allows for the transformation of speed and torque. By adjusting the pulley sizes and ratios, the gearbox can modify the mechanical advantage to accommodate different load and torque requirements. This mechanical advantage compensates for variations in load and enables the gearbox to deliver the necessary torque to overcome resistance or deliver power efficiently.

Pulley Configurations: Pulley gearboxes can be designed with various pulley configurations to handle load and torque variations effectively. For example, compound pulley systems can be employed to provide multiple stages of speed reduction or increase, allowing for finer control over torque and speed. Multiple belts or ropes can also be used to distribute the load across several pulleys, reducing stress on individual components and enhancing the gearbox’s ability to handle variations in load and torque.

Adjustable Pulley Systems: Some pulley gearboxes incorporate adjustable pulley systems, such as variable speed drives or tension-adjustable pulleys. These systems allow for on-the-fly adjustment of the pulley sizes or tension, enabling the gearbox to adapt to changing load and torque conditions. By adjusting the pulley ratio or tension, the gearbox can optimize the speed, torque, and power transmission efficiency based on the specific requirements of the application.

Load Sensing and Feedback Mechanisms: In certain applications, pulley gearboxes may be equipped with load sensing and feedback mechanisms. These mechanisms monitor the load or torque being exerted on the gearbox and provide feedback signals that can be used to adjust the pulley ratios or control other aspects of the system. Load sensing and feedback mechanisms help optimize the performance of the gearbox by dynamically responding to variations in load and torque, ensuring efficient power transmission and preventing overload or underload conditions.

System Design and Overload Protection: The overall design of the pulley gearbox can also contribute to its ability to handle variations in load and torque. Robust construction, appropriate selection of materials, and careful engineering considerations ensure that the gearbox can withstand high loads and torque without failure. Additionally, overload protection mechanisms, such as torque limiters or safety clutches, can be incorporated to safeguard the gearbox and other components from damage in the event of sudden or excessive loads.

Regular Maintenance: Proper maintenance practices, including regular inspection, lubrication, and component replacement, are essential for ensuring the optimal performance and longevity of pulley gearboxes. By maintaining the gearbox in good working condition, potential issues that may arise from load and torque variations can be identified and addressed early, reducing the risk of failure and improving overall reliability.

In summary, pulley gearboxes handle variations in load and torque during operation through the mechanical advantage provided by the pulley system, adjustable pulley configurations, load sensing and feedback mechanisms, robust system design, and regular maintenance. These features allow pulley gearboxes to adapt to changing load conditions, deliver the required torque, and ensure efficient power transmission in a wide range of applications.

How do pulley gearboxes handle variations in speed ratios and torque requirements?

Pulley gearboxes are designed to handle variations in speed ratios and torque requirements by utilizing different pulley sizes, configurations, and mechanical principles. They offer flexibility and adaptability in adjusting speed and torque according to specific application needs. Here’s a detailed explanation of how pulley gearboxes handle variations in speed ratios and torque requirements:

Pulley Size and Configuration:

Pulley gearboxes employ pulleys of different sizes and configurations to achieve the desired speed ratios and torque requirements. By varying the diameters of the driving and driven pulleys, the rotational speed can be adjusted. Larger driving pulleys and smaller driven pulleys result in a higher speed ratio, while smaller driving pulleys and larger driven pulleys lead to a lower speed ratio. The selection of pulley sizes allows for precise control over speed variations in pulley gearboxes.

Mechanical Advantage:

The mechanical advantage provided by pulley gearboxes allows them to handle variations in torque requirements. Pulley gearboxes utilize the principle of mechanical advantage, where the larger pulley transfers more torque to the smaller pulley. This allows the gearbox to increase or decrease the torque output while maintaining a consistent speed ratio. By adjusting the pulley sizes and the mechanical advantage, pulley gearboxes can match the torque requirements of the driven machinery or system.

Tension and Friction:

Tension and friction play a crucial role in how pulley gearboxes handle variations in speed ratios and torque requirements. The tension in the belts or ropes connecting the driving and driven pulleys helps maintain a firm grip and prevent slippage, ensuring reliable power transmission. By adjusting the tension, the efficiency of power transmission can be optimized. The friction between the belts or ropes and the pulleys also contributes to the handling of torque variations. The frictional force allows for the transfer of torque from the driving pulley to the driven pulley, accommodating changes in torque requirements.

Adjustability:

Pulley gearboxes offer adjustability, allowing for variations in speed ratios and torque requirements. The pulleys can be moved or adjusted to change the effective diameter or position, altering the speed and torque output. This adjustability enables precise control over the performance of the gearbox, making it adaptable to different operational needs and load conditions.

Compound Pulley Systems:

Compound pulley systems are another mechanism used in pulley gearboxes to handle variations in speed ratios and torque requirements. These systems consist of multiple pulleys arranged in series or parallel configurations, incorporating intermediate pulleys and idler pulleys. The compound pulley systems allow for complex speed and torque conversions, providing a wider range of speed ratios and torque capabilities.

Overall, pulley gearboxes handle variations in speed ratios and torque requirements through a combination of pulley size and configuration, mechanical advantage, tension and friction control, adjustability, and the utilization of compound pulley systems. These features enable pulley gearboxes to efficiently transmit power, control speed, and adapt to different operational demands in a wide range of industrial applications.

editor by CX 2024-03-09