Product Description

SMR Shaft Mounted Flat Type Motor Reduction Gear Box for Belt Conveyor Drive

Features:

1. High strength of gear box, gears and shafts, sturdy and durable

2. 2 metric output shaft bore diameters (Standard and Optional)

3. Optional backstop to prevent backdriving. Backstop is not recommended for the gear ratio 5

4. Double lips skeleton oil seal combines the functions of seal and dust-proof

5. Widely used in belt conveyor and pulley drive system

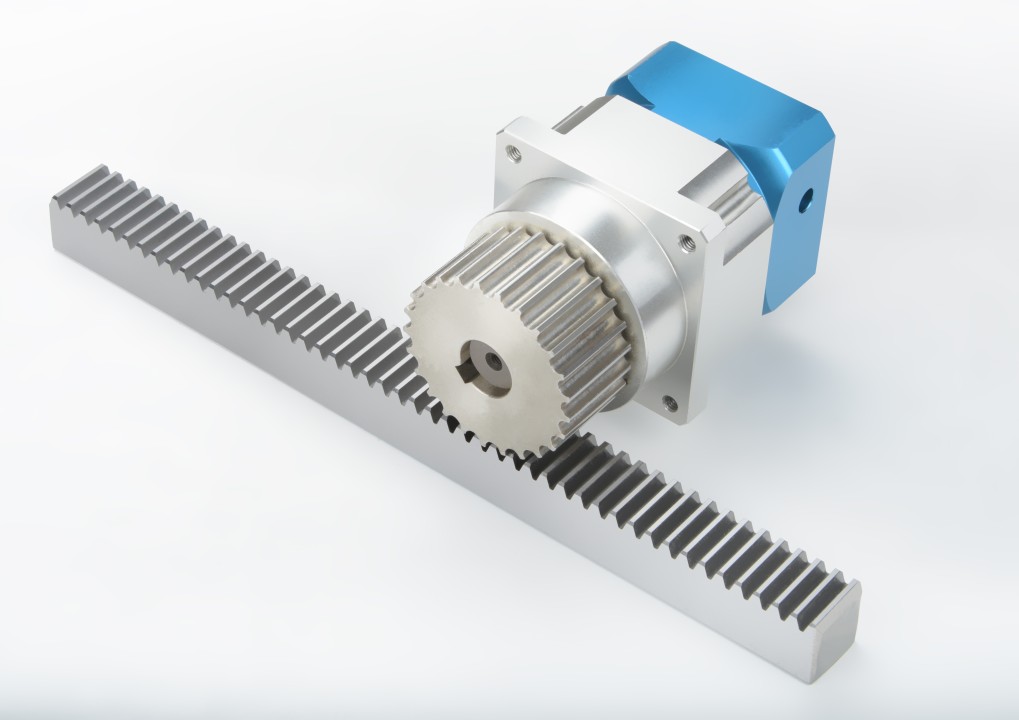

Product photo:

Specification for shaft mounted gearbox:

FAQ

Q: Can you make the gearbox with customization?

A: Yes, we can customize per your request, like flange, shaft, configuration, material, etc.

Q: Do you provide samples?

A: Yes. Sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard product need 5-30days, a bit longer for customized products.

Q: Do you provide technology support?

A: Yes. Our company have design and development team, we can provide technology support if you

need.

Q: How to ship to us?

A: It is available by air, or by sea, or by train.

Q: How to pay the money?

A: T/T and L/C is preferred, with different currency, including USD, EUR, RMB, etc.

Q: How can I know the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send inquiry directly, and we will respond within 24 hours.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Belt Conveyor and Pulley Drive System |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | Order Sample 1pc for the normal type and design

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide real-world examples of products that use pulley gearbox technology?

Pulley gearbox technology finds application in various industries and products where speed reduction, torque multiplication, and efficient power transmission are required. Here are some real-world examples of products that commonly use pulley gearbox technology:

Automotive Industry: Pulley gearboxes are widely used in automotive applications to transmit power and control rotational speed. One prominent example is the continuously variable transmission (CVT) system, which utilizes a pulley gearbox to provide seamless and efficient speed control. CVTs are found in many modern passenger vehicles, where they offer improved fuel efficiency by continuously adjusting the gear ratio to match the driving conditions. Pulley gearboxes are also employed in engine accessory drives, such as alternator drives, air conditioning compressor drives, and power steering systems.

Industrial Machinery: Pulley gearboxes are commonly utilized in various industrial machinery and equipment. Belt-driven machines, such as conveyor systems, packaging equipment, and material handling systems, often incorporate pulley gearboxes to transmit power and control speed. These gearboxes enable efficient power transfer and allow for easy speed adjustment to match specific application requirements. Additionally, pulley gearboxes are used in machine tools, textile machinery, printing presses, and many other industrial applications where precise speed control, torque multiplication, and energy efficiency are essential.

Exercise Equipment: Many types of exercise equipment, including treadmills, elliptical machines, and stationary bikes, utilize pulley gearboxes. These gearboxes are responsible for transmitting power from the motor to the moving components, such as the running belt or pedal assembly. By incorporating pulley gearboxes, exercise equipment manufacturers can provide users with adjustable speed settings and variable resistance levels, allowing for customized workouts and efficient energy utilization.

Home Appliances: Pulley gearboxes can be found in various home appliances where speed reduction and efficient power transmission are required. For example, washing machines often utilize pulley gearboxes to control the drum’s rotational speed during different wash cycles. Similarly, certain types of blenders and mixers use pulley gearboxes to achieve multiple speed settings for food preparation tasks. The gearboxes enable efficient power transfer and allow users to select the desired speed based on the specific application.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems commonly employ pulley gearboxes in their fan assemblies. These gearboxes enable speed control and ensure that the fans operate at the desired rotational speed for efficient air circulation. By adjusting the pulley sizes or gear ratios, the airflow can be optimized to match the cooling or heating demands of the space, resulting in energy savings and improved HVAC system performance.

Farming and Agricultural Equipment: Pulley gearboxes are utilized in various farming and agricultural equipment to transmit power and control rotational speed. Equipment such as combine harvesters, hay balers, and irrigation systems often incorporate pulley gearboxes to drive and control the speed of different components. These gearboxes enable efficient power transmission and help optimize the operation of agricultural machinery for improved productivity and reduced energy consumption.

Power Tools: Pulley gearboxes are also present in certain power tools to provide speed control and torque multiplication. Examples include bench grinders, drill presses, band saws, and woodworking equipment. By incorporating pulley gearboxes, power tool manufacturers can offer users the flexibility to adjust the speed and optimize the tool’s performance for various applications, while ensuring efficient power transfer and reduced power consumption.

Entertainment Industry: In the entertainment industry, pulley gearboxes are utilized in various equipment and devices. Examples include stage machinery for theater productions, where pulley gearboxes are used to control the movement of curtains, scenery, and other stage elements. Pulley gearboxes are also found in amusement park rides, enabling precise speed control and ensuring the safety and enjoyment of the riders.

These are just a few examples of the wide range of products and industries that utilize pulley gearbox technology. The versatility and efficiency of pulley gearboxes make them a valuable component in numerous applications where power transmission, speed control, and energy efficiency are essential.

How do gear ratios in pulley gearboxes impact their performance?

The gear ratios in pulley gearboxes have a significant impact on their performance, influencing factors such as speed, torque, and power transmission efficiency. By adjusting the gear ratios, the performance characteristics of the pulley gearbox can be tailored to meet specific application requirements. Here’s a detailed explanation of how gear ratios affect the performance of pulley gearboxes:

Speed: The gear ratio determines the speed relationship between the driving and driven pulleys in a pulley gearbox. A higher gear ratio, achieved by using a smaller driven pulley or a larger driving pulley, results in a slower output speed compared to the input speed. Conversely, a lower gear ratio, achieved by using a larger driven pulley or a smaller driving pulley, leads to a higher output speed. By selecting the appropriate gear ratio, the speed of the driven pulley can be adjusted to meet the desired operational requirements.

Torque: Gear ratios also affect the torque output of the pulley gearbox. The torque is inversely proportional to the gear ratio, meaning that a higher gear ratio results in increased torque at the driven pulley, while a lower gear ratio reduces the torque. This is due to the mechanical advantage provided by the pulley system. By adjusting the gear ratio, the torque output can be optimized to match the torque requirements of the load being driven by the gearbox. Higher gear ratios are useful in applications that require greater torque, such as lifting heavy loads, while lower gear ratios are beneficial for applications that prioritize higher rotational speed.

Power Transmission Efficiency: The gear ratios play a role in determining the power transmission efficiency of pulley gearboxes. Generally, pulley gearboxes with higher gear ratios tend to have lower power transmission efficiency. This is primarily due to increased friction and energy losses associated with the mechanical advantage provided by smaller driven pulleys or larger driving pulleys. On the other hand, lower gear ratios typically result in higher power transmission efficiency. To optimize the overall performance of the pulley gearbox, it is essential to select gear ratios that strike a balance between the desired speed, torque, and power transmission efficiency.

Operational Range: The range of operation of a pulley gearbox is influenced by the available gear ratios. Different gear ratios provide different speed and torque ranges, allowing the gearbox to adapt to a variety of load conditions. By incorporating multiple pulleys, adjustable pulley systems, or variable speed drives, pulley gearboxes can offer a broader operational range. This flexibility enables the gearbox to handle a wide range of applications and accommodate varying speed and torque requirements.

System Design: Gear ratios also impact the overall design of the pulley gearbox. The selection of gear ratios influences the size, arrangement, and number of pulleys required in the system. Higher gear ratios may require smaller driven pulleys or larger driving pulleys, which can influence the physical dimensions and layout of the gearbox. It is important to consider the space constraints, load requirements, and other design considerations when determining the optimal gear ratios for a pulley gearbox.

In summary, gear ratios in pulley gearboxes have a significant impact on their performance characteristics. By adjusting the gear ratios, the speed, torque, power transmission efficiency, operational range, and overall design of the pulley gearbox can be tailored to meet specific application requirements. Careful consideration of the desired performance parameters is essential when selecting and designing pulley gearboxes to ensure optimal performance and efficient power transmission.

What is a pulley gearbox and how does it function in mechanical systems?

A pulley gearbox, also known as a pulley system or pulley transmission, is a mechanical device that utilizes pulleys and belts or ropes to transmit power and torque between rotating shafts. It functions by changing the speed and direction of rotation while maintaining a constant power output. Here’s a detailed explanation of the pulley gearbox and its functioning in mechanical systems:

Definition and Components:

A pulley gearbox consists of several components, including pulleys, belts or ropes, and a tensioning mechanism. The pulleys are circular wheels with grooves along their circumference to hold the belts or ropes. The belts or ropes are flexible elements that wrap around the pulleys, forming a loop. The tensioning mechanism ensures proper tension in the belts or ropes to prevent slippage and ensure efficient power transmission.

Speed and Torque Conversion:

The primary function of a pulley gearbox is to convert the speed and torque between two rotating shafts. This is achieved by using pulleys of different sizes. The size of a pulley is determined by its diameter. The larger the diameter of a pulley, the slower it rotates, and vice versa. By connecting pulleys of different sizes with belts or ropes, the rotational speed can be increased or decreased, allowing for speed conversion in the mechanical system.

When the driving pulley (connected to the input shaft) has a smaller diameter than the driven pulley (connected to the output shaft), the speed is increased, but the torque is reduced. This configuration is referred to as an speed increaser or speed-up pulley system. Conversely, when the driving pulley has a larger diameter than the driven pulley, the speed is decreased, but the torque is increased. This configuration is referred to as a speed reducer or speed-down pulley system.

Multiple Pulley Configurations:

Pulley gearboxes can be designed with multiple pulleys and belts or ropes to create more complex speed and torque conversion systems. These configurations can involve additional intermediate pulleys and idler pulleys to redirect the belt or rope path. By combining pulleys of different sizes and arranging them in various configurations, the pulley gearbox can achieve specific speed and torque ratios to suit the requirements of the mechanical system.

Advantages and Applications:

The pulley gearbox offers several advantages in mechanical systems:

- Simplicity: Pulley gearboxes are relatively simple in design and construction, making them cost-effective and easy to manufacture.

- Smooth Operation: The use of belts or ropes in the pulley system helps absorb shocks and vibrations, resulting in smoother operation and reduced noise.

- Adjustability: The speed ratio of a pulley gearbox can be easily adjusted by changing the sizes of the pulleys, allowing for flexibility in adapting to different operational requirements.

- Non-slip Power Transmission: The friction between the belts or ropes and the pulleys ensures efficient power transmission without slippage, even under varying load conditions.

- Compact Size: Pulley gearboxes can be designed in compact sizes, making them suitable for applications where space is limited.

Pulley gearboxes find applications in various mechanical systems, including conveyor systems, industrial machinery, agricultural equipment, automotive accessories, exercise machines, and more. They are particularly useful in situations where speed and torque conversion, adjustability, and smooth power transmission are required.

editor by CX 2024-02-05