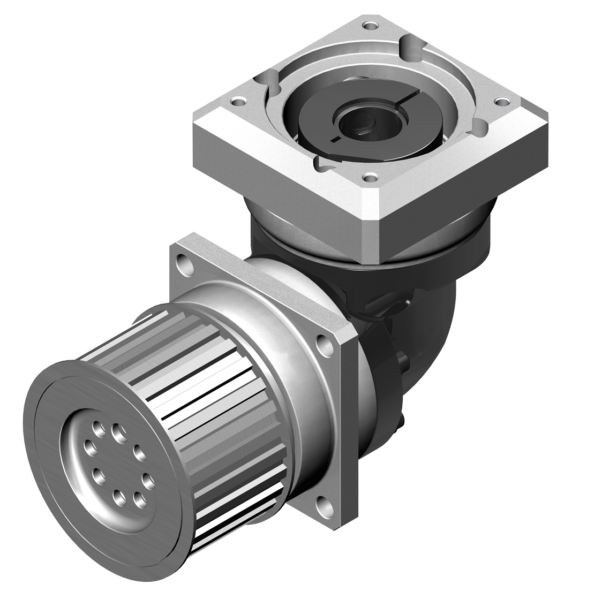

Product Description

Precision planetary gear reducer is a new-generation of product developed by our company, with a compromise of advanced technology both at home and abroad, its main features are as follows:

1. Low noise: under 65db.

2. Low backlash: within 3 arcmin.

3. High efficiency: 97% for 1 stage, 94% for 2 stages.

4. High input speed: Rated input speed 3000rpm, max input speed 6000 rpm.

5. High output torque: higher torque output than that of conventional planetary gear reducer.

6. High stability hardening,which extends gear service life and maintain high accuracy as new after a long period of operation.

Precicion planetary gear reducer is widely used in the following fields:

1. Aerospace industries.

2. Medical health, electronic information industries.

3. Industrial robots, productin automation, CNC machine tool manufacturing industries.

4. Motor,textile,printing,food,metallurgical,envrironment protection engineering, warehouse logistics industries.

About Xingda since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamp

ing field since 1984. Our main product, NMRV worm gear speed reducer and series helical gearbox, XDR,

XDF, XDK, XDShave reached the advanced technique index of the congeneric European and Janpanese produc

ts, We offer standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders

of non-standard products, such as gears, shafts, punching parts ect, according to customers’ Drawings or sam-

ples.

Our company has complete set of equipment including CNC, lathes, milling machines, gear hobbing machine, g-

ear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding machines, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing machines and s-

o on. We have advanced testing equipments also.

Our company has established favorable cooperation relationships with sub-suppliers involving casting, raw mat-

erial, heat treatment, surface finishing and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Gear Shape: | Helical |

| Step: | Single-Step |

| Type: | Planetary Gear Reducer |

| Samples: |

US$ 230/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do pulley gearboxes contribute to optimizing the efficiency of conveyor systems?

Pulley gearboxes play a crucial role in optimizing the efficiency of conveyor systems, which are widely used in industries for material handling and transportation. By providing speed control, torque multiplication, and efficient power transmission, pulley gearboxes offer several benefits that contribute to the overall efficiency of conveyor systems. Here’s a detailed explanation of how pulley gearboxes optimize conveyor system efficiency:

Speed Control: One of the key advantages of pulley gearboxes in conveyor systems is their ability to control the rotational speed of the conveyor belt. By adjusting the pulley sizes or changing the gear ratio, the speed of the conveyor belt can be precisely regulated to match the specific requirements of the application. This speed control capability allows for optimal material handling, preventing unnecessary energy consumption or strain on the system. For instance, in situations where lighter loads or delicate materials are being transported, the speed can be reduced to avoid excessive impact or spillage. On the other hand, for heavy loads or time-sensitive operations, the speed can be increased to maximize productivity. By adapting the speed to the specific needs of the material and operation, pulley gearboxes optimize the efficiency of conveyor systems.

Torque Multiplication: Pulley gearboxes are designed to provide torque multiplication, allowing higher torque to be delivered at the output pulley compared to the input pulley. This torque multiplication capability is particularly beneficial in conveyor systems that handle heavy loads or encounter resistance during operation. By multiplying the torque, pulley gearboxes enable the conveyor system to overcome these challenges more effectively, reducing the risk of belt slippage or motor overload. The increased torque also allows for the use of smaller and more efficient motors, contributing to energy savings and improved efficiency. Torque multiplication provided by pulley gearboxes ensures that the conveyor system operates at its optimal performance level, enhancing overall efficiency.

Efficient Power Transmission: Pulley gearboxes utilize belts or chains to transmit power from the input pulley to the output pulley. These flexible power transmission elements offer several advantages for conveyor systems. Firstly, they absorb vibrations and dampen shocks, reducing the impact on the system components and improving overall reliability. Secondly, belts or chains allow for slight misalignments and flexibility in the conveyor system, compensating for variations and ensuring smooth operation. Furthermore, the use of belts or chains helps to minimize noise generation during operation. Overall, the efficient power transmission provided by pulley gearboxes ensures minimal power losses and maximizes the energy transfer to the conveyor belt, optimizing the efficiency of the system.

Load Matching: Conveyor systems often encounter variations in load conditions, with different weights and types of materials being transported. Pulley gearboxes enable load matching by allowing for the adjustment of speed and torque output to match the specific load requirements. By selecting the appropriate pulley sizes or gear ratios, the pulley gearbox can be optimized to deliver the necessary speed and torque for efficient material handling. This load matching capability ensures that the conveyor system operates at its most efficient point, minimizing energy losses and reducing power consumption. It also helps to prevent unnecessary wear and tear on the system components, prolonging their lifespan and reducing maintenance requirements.

System Integration: Pulley gearboxes are integrated components within conveyor systems, designed to work seamlessly with other system elements. This integration allows for efficient power transfer and synchronization between the motor, pulleys, and conveyor belt. The proper selection and sizing of pulley gearboxes, along with other components such as motors, bearings, and belts, contribute to the overall efficiency of the conveyor system. By ensuring that all system elements work together harmoniously, pulley gearboxes optimize the performance and energy consumption of the conveyor system as a whole.

Maintenance and Reliability: Efficient maintenance practices and reliable operation are crucial for optimizing the efficiency of conveyor systems. Pulley gearboxes are designed to be durable and require minimal maintenance. Regular inspection and lubrication of the gearboxes help ensure smooth operation and minimize friction losses. Additionally, pulley gearboxes are often equipped with features such as seals and guards to protect against contaminants and prevent premature wear. By maintaining the reliability and performance of the pulley gearboxes, conveyor systems can operate at their highest efficiency, reducing downtime and optimizing productivity.

In summary, pulley gearboxes contribute to optimizing the efficiency of conveyor systems by providing speed control, torque multiplication, efficient power transmission, load matching, and seamless integration with other system components. By leveraging these advantages, conveyor systems can operate at their optimal performance levels, minimizing energy consumption, reducing downtime, and maximizing productivity.

Can pulley gearboxes be used for both speed reduction and speed increase?

Yes, pulley gearboxes can be used for both speed reduction and speed increase, depending on the configuration and arrangement of the pulleys. The versatility of pulley gearboxes allows them to adapt to different applications and provide the desired speed variations. Here’s a detailed explanation:

Pulley gearboxes consist of two or more pulleys connected by belts or ropes. The driving pulley is connected to the power source, while the driven pulley is connected to the load. The size and ratio of the pulleys determine the speed relationship between the driving and driven pulleys.

For speed reduction, a larger driving pulley can be combined with a smaller driven pulley. As the driving pulley rotates at a higher speed, the smaller driven pulley rotates at a slower speed. This speed reduction is achieved by the mechanical advantage provided by the different pulley sizes, resulting in a lower output speed and increased torque at the driven pulley. Speed reduction is commonly used in applications where the load requires higher torque and lower rotational speed.

On the other hand, for speed increase, a smaller driving pulley can be combined with a larger driven pulley. As the driving pulley rotates at a lower speed, the larger driven pulley rotates at a higher speed. This speed increase is achieved by the mechanical advantage provided by the different pulley sizes, resulting in a higher output speed and reduced torque at the driven pulley. Speed increase is useful in applications that require higher rotational speed and lower torque.

It’s important to note that the speed ratio between the driving and driven pulleys is not solely determined by the pulley sizes but also influenced by the number of pulleys and their arrangement. By incorporating additional pulleys and using various configurations, such as compound pulley systems or multiple belt drives, more complex speed ratios can be achieved, providing a wider range of speed reduction and increase options.

Furthermore, pulley gearboxes can also incorporate adjustable pulley systems or variable speed drives to provide even more flexibility in speed control. These mechanisms allow for on-the-fly adjustment of the pulley sizes, enabling precise speed regulation and accommodating changing operational requirements.

In summary, pulley gearboxes can be utilized for both speed reduction and speed increase by selecting appropriate pulley sizes and configurations. The mechanical advantage provided by the pulley system allows for versatile speed variations, making pulley gearboxes a flexible option for a wide range of applications.

Are there variations in pulley gearbox designs for different load conditions?

Yes, there are variations in pulley gearbox designs to cater to different load conditions. The design of a pulley gearbox takes into account the specific load requirements, including the magnitude of the load, the nature of the load (constant or variable), and the duty cycle of the application. Here’s a detailed explanation of the variations in pulley gearbox designs for different load conditions:

- Heavy-Duty Load Conditions: For applications that involve heavy loads or high torque requirements, pulley gearboxes are designed with robust and durable components. These gearboxes are constructed using materials with high tensile strength and are engineered to withstand the stress and forces associated with heavy loads. Additionally, the pulley sizes and configurations are optimized to provide the necessary mechanical advantage and torque transfer capabilities.

- Light to Moderate Load Conditions: Pulley gearboxes designed for light to moderate load conditions may feature lighter and more compact designs. They are typically constructed using materials that offer a balance between strength and weight, optimizing the gearbox’s efficiency and performance for the specific load requirements. The pulley sizes and configurations are selected to provide the desired speed ratios and torque output while considering the load’s magnitude.

- Variable Load Conditions: In applications where the load conditions vary or are subject to fluctuations, pulley gearboxes may incorporate features to handle these variations. This can include adjustable pulley systems that allow for quick changes in speed ratios and torque output. The gearbox may also be designed to accommodate dynamic load conditions, with components engineered to absorb shocks and vibrations resulting from load variations.

- Continuous Duty Load Conditions: For applications that require continuous operation under load, pulley gearboxes are designed with considerations for heat dissipation and durability. They may incorporate cooling mechanisms such as fans or heat sinks to maintain optimal operating temperatures. The gearbox housing and components are designed to withstand prolonged operation and minimize wear and tear.

- Cyclic or Intermittent Load Conditions: Pulley gearboxes used in applications with cyclic or intermittent load conditions may be designed to handle the specific duty cycle. The gearbox may incorporate features such as enhanced lubrication systems to minimize friction and wear during start-stop cycles. The materials and construction may be optimized to withstand the repetitive loading and unloading cycles without compromising performance or reliability.

Overall, pulley gearbox designs can vary significantly depending on the load conditions they are intended to handle. The selection of materials, construction methods, pulley configurations, and additional features are all tailored to ensure optimal performance, durability, and efficiency for the specific load requirements of the application.

editor by CX 2024-04-04