Product Description

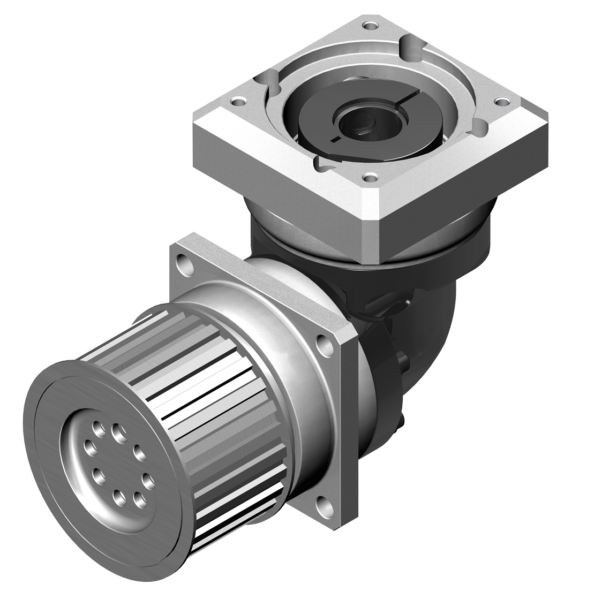

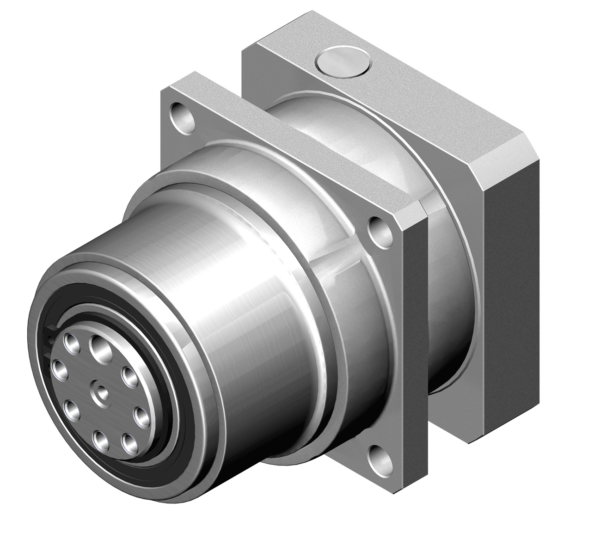

High Performance Worm Gearbox Reduction For Conveyor Mill Machine

Features:

1) Aluminum alloy die-casted gearbox

2) Compact structure saves mounting space

3) Highly accurate

4) Runs CHINAMFG and backward

5) High overload capacity

6) Stable transmission with reduced vibration and noise

Characteristics:

1. High quality aluminum alloy quadrate case .

2. High efficiency.

3. Small size, compact constructure and light weight.

4. Combination of 2 single-step worm gear speed reducers, meeting the requirements of super speed ratio.

Technical Data:

1. Input power: 0.06kW-15kW

2. Output torque: 7.8-1195N.m

3. Speed ratio: (5-100) 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100

4. Adapt for IEC, NEMA, SERVO

Materials:

1. From RV25 up to RV105: Aluminium alloy housing.

2. From RV110 to RV150: Cast iron housing.

3. Seal: CHINAMFG Seal from ZheJiang

4. Bearing :homemade Bearing

Color:

1. RAL5571

2. Blue

3. Silver

Quality control:

1.Quality guarantee: 1 year

2.Certificate of quality: ISO9001:2008

3.Every product must be tested before packing

General Technical data:

Size number:25,30,40,50,63,75,90,110,130,150

Ratio:1/100-1/5000

Color:blue,silver,RAL5571 color

Material:housing -casting iron- HT200-250#/aluminum worm gear-KK alloy worm-20CrMnTi with carburizing and quenching,surface hardness is 58-62HRC shaft-chromium steel-45#

Packing: Inner pack: use plastic bag a Inner pack: use plastic bag and foam box, outer pack: carton or wooden case 1set/bag/carton or based on customer’s requestbearing: CHINAMFG & Homemade bearing

Seal: CHINAMFG seal from ZheJiang

Input power: 0.25kw,0.37kw,0.55kw,0.75kw,1.1kw,1.5kw,2.2kw,3.0kw,4.0kw,5.5kw,7.5kw

Lubricant:Synthetic & Mineral

IEC flange:56B5,63B5,71B5,80B5,90B5,100B5,112B5,132B5

Output form: CHINAMFG shaft,hollow shaft weight: 0.7-87.8KGSapplication: In industrial machine:food Stuff,ceramics,chemical,packing,printing,dyeing,woodworking,glass and plastics

Warranty:1 year

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery |

|---|---|

| Function: | Speed Changing, Speed Reduction |

| Layout: | helical |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Four-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any limitations or disadvantages associated with pulley gearbox systems?

While pulley gearbox systems offer several advantages, they also have certain limitations and disadvantages that should be taken into consideration. Here’s a detailed explanation of some of the limitations and disadvantages associated with pulley gearbox systems:

Limited Gear Ratio Range: Pulley gearboxes have a limited range of gear ratios compared to other types of gearboxes, such as spur or planetary gearboxes. The gear ratio range is determined by the available pulley sizes and configurations. In some cases, achieving extremely high or low gear ratios may require impractically large or small pulleys, which can limit the design flexibility and operational range of the gearbox.

Slippage and Belt Tension: Pulley gearboxes rely on belts or ropes to transmit power between the driving and driven pulleys. However, these flexible power transmission elements can experience slippage under certain conditions, leading to a loss of efficiency and accuracy in power transmission. Maintaining proper belt tension is crucial to minimize slippage, but it requires regular monitoring and adjustment. Additionally, excessive belt tension can lead to increased wear and tear on the belts and pulleys.

Limited Precision and Backlash: Pulley gearboxes may have limitations in terms of precision and backlash compared to other gearbox types. Backlash refers to the slight movement or play that occurs when switching rotational direction in the gearbox. While backlash can be minimized through careful design and manufacturing techniques, pulley gearboxes may have inherent backlash due to the nature of the flexible power transmission elements, such as belts or ropes. This can impact the accuracy of motion control applications that require precise positioning or synchronization.

Limited Power Transmission Capacity: Pulley gearboxes may have limitations on their power transmission capacity compared to gearboxes with rigid gear elements, such as spur or helical gearboxes. The power transmission capacity of a pulley gearbox depends on factors such as the strength and material of the belts or ropes, as well as the pulley sizes and configurations. In applications that require high torque or heavy-duty operation, other types of gearboxes may be better suited due to their ability to handle greater power transmission requirements.

Maintenance and Belt Replacement: Pulley gearboxes require regular maintenance, including belt inspection, adjustment, and replacement. Belts are subject to wear and aging over time, and their performance can deteriorate, leading to reduced efficiency and increased risk of failure. Maintaining proper belt tension, monitoring belt condition, and scheduling regular belt replacements are necessary to ensure the reliable operation of pulley gearboxes. This maintenance requirement adds to the overall cost and effort associated with operating pulley gearbox systems.

Complexity with Multiple Pulley Systems: Pulley gearboxes that incorporate multiple pulleys and complex configurations can introduce additional complexity in terms of design, installation, and maintenance. The interaction of multiple belts or ropes, as well as the adjustment of various pulley sizes and positions, can become more challenging, requiring careful alignment and synchronization. This complexity can increase the risk of misalignment, slippage, or other operational issues if not properly managed.

Space and Layout Considerations: Pulley gearboxes, especially those with multiple pulleys, may require more space compared to other compact gearbox designs. The size and arrangement of the pulleys can impact the overall dimensions and layout of the gearbox system. This can be a limitation in applications with limited space or specific installation constraints where compactness is a critical requirement.

Despite these limitations and disadvantages, pulley gearbox systems remain widely used and provide practical solutions in many applications. The key is to carefully assess the specific requirements of the application and consider factors such as torque, speed, precision, power transmission capacity, maintenance needs, and space constraints to determine if a pulley gearbox is the most suitable choice.

Can pulley gearboxes be used for both speed reduction and speed increase?

Yes, pulley gearboxes can be used for both speed reduction and speed increase, depending on the configuration and arrangement of the pulleys. The versatility of pulley gearboxes allows them to adapt to different applications and provide the desired speed variations. Here’s a detailed explanation:

Pulley gearboxes consist of two or more pulleys connected by belts or ropes. The driving pulley is connected to the power source, while the driven pulley is connected to the load. The size and ratio of the pulleys determine the speed relationship between the driving and driven pulleys.

For speed reduction, a larger driving pulley can be combined with a smaller driven pulley. As the driving pulley rotates at a higher speed, the smaller driven pulley rotates at a slower speed. This speed reduction is achieved by the mechanical advantage provided by the different pulley sizes, resulting in a lower output speed and increased torque at the driven pulley. Speed reduction is commonly used in applications where the load requires higher torque and lower rotational speed.

On the other hand, for speed increase, a smaller driving pulley can be combined with a larger driven pulley. As the driving pulley rotates at a lower speed, the larger driven pulley rotates at a higher speed. This speed increase is achieved by the mechanical advantage provided by the different pulley sizes, resulting in a higher output speed and reduced torque at the driven pulley. Speed increase is useful in applications that require higher rotational speed and lower torque.

It’s important to note that the speed ratio between the driving and driven pulleys is not solely determined by the pulley sizes but also influenced by the number of pulleys and their arrangement. By incorporating additional pulleys and using various configurations, such as compound pulley systems or multiple belt drives, more complex speed ratios can be achieved, providing a wider range of speed reduction and increase options.

Furthermore, pulley gearboxes can also incorporate adjustable pulley systems or variable speed drives to provide even more flexibility in speed control. These mechanisms allow for on-the-fly adjustment of the pulley sizes, enabling precise speed regulation and accommodating changing operational requirements.

In summary, pulley gearboxes can be utilized for both speed reduction and speed increase by selecting appropriate pulley sizes and configurations. The mechanical advantage provided by the pulley system allows for versatile speed variations, making pulley gearboxes a flexible option for a wide range of applications.

What benefits do pulley gearboxes offer in various industrial applications?

Pulley gearboxes provide numerous benefits in various industrial applications. They offer advantages that contribute to efficient power transmission, speed control, versatility, and reliability. Here’s a detailed explanation of the benefits that pulley gearboxes offer in industrial applications:

- Power Transmission: Pulley gearboxes excel at power transmission between rotating shafts. They efficiently transfer rotational force and torque through the use of belts or ropes and pulleys. The friction between the belts or ropes and the pulleys ensures reliable power transmission without slippage, enabling the transfer of power from the driving pulley to the driven pulley.

- Speed Control: Pulley gearboxes allow for precise speed control in industrial applications. By utilizing pulleys of different sizes, the rotational speed can be adjusted according to specific operational requirements. The adjustability of pulley gearboxes facilitates speed conversion, enabling the system to operate at the desired speed while maintaining efficient power transmission.

- Flexibility and Adaptability: Pulley gearboxes offer flexibility and adaptability in industrial applications. They can be easily configured with different pulley sizes and arrangements to achieve specific speed and torque ratios. This versatility allows pulley gearboxes to adapt to varying load conditions, operational requirements, and system constraints, making them suitable for a wide range of industrial applications.

- Compact Size: Pulley gearboxes can be designed in compact sizes, making them ideal for industrial applications where space is limited. Their compact form factor allows for easy integration into machinery and equipment without occupying excessive space, optimizing the layout and efficiency of industrial systems.

- Cost-Effectiveness: Pulley gearboxes offer a cost-effective solution for power transmission and speed control in industrial applications. They are relatively simple in design and construction, resulting in lower manufacturing costs compared to more complex gearbox alternatives. The cost-effectiveness of pulley gearboxes makes them an attractive choice for industrial applications where budget constraints are a consideration.

- Reliability: Pulley gearboxes are known for their reliability in industrial settings. The use of belts or ropes in the pulley system helps absorb shocks and vibrations, reducing the risk of component failure and ensuring smooth operation. The frictional power transmission mechanism of pulley gearboxes provides robust and dependable performance, enhancing the overall reliability and longevity of industrial systems.

- Wide Range of Applications: Pulley gearboxes find applications in various industrial sectors. They are utilized in conveyor systems, manufacturing equipment, material handling machinery, agricultural machinery, automotive accessories, fitness equipment, and more. The versatility of pulley gearboxes makes them suitable for diverse industrial applications where power transmission, speed control, and adaptability are essential.

The benefits offered by pulley gearboxes in industrial applications, including efficient power transmission, precise speed control, flexibility, compact size, cost-effectiveness, reliability, and versatility, make them a popular choice for engineers and designers. By leveraging the advantages of pulley gearboxes, industrial systems can achieve optimized performance, improved productivity, and enhanced operational efficiency.

editor by CX 2024-04-10