Product Description

High Precision NMRV Series Worm Gearbox For Tractor

Features:

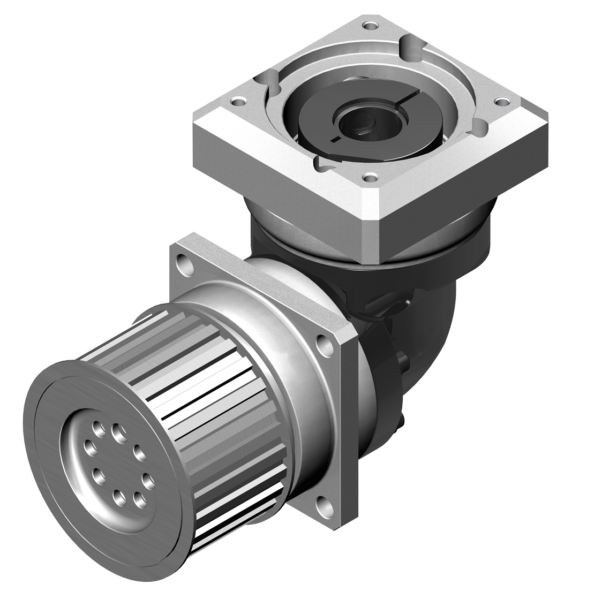

1) Aluminum alloy die-casted gearbox

2) Compact structure saves mounting space

3) Highly accurate

4) Runs CHINAMFG and backward

5) High overload capacity

6) Stable transmission with reduced vibration and noise

Characteristics:

1. High quality aluminum alloy quadrate case .

2. High efficiency.

3. Small size, compact constructure and light weight.

4. Combination of 2 single-step worm gear speed reducers, meeting the requirements of super speed ratio.

Technical Data:

1. Input power: 0.06kW-15kW

2. Output torque: 7.8-1195N.m

3. Speed ratio: (5-100) 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100

4. Adapt for IEC, NEMA, SERVO

Materials:

1. From RV25 up to RV105: Aluminium alloy housing.

2. From RV110 to RV150: Cast iron housing.

3. Seal: CHINAMFG Seal from ZheJiang

4. Bearing :homemade Bearing

Color:

1. RAL5571

2. Blue

3. Silver

Quality control:

1.Quality guarantee: 1 year

2.Certificate of quality: ISO9001:2008

3.Every product must be tested before packing

General Technical data:

Size number:25,30,40,50,63,75,90,110,130,150

Ratio:1/100-1/5000

Color:blue,silver,RAL5571 color

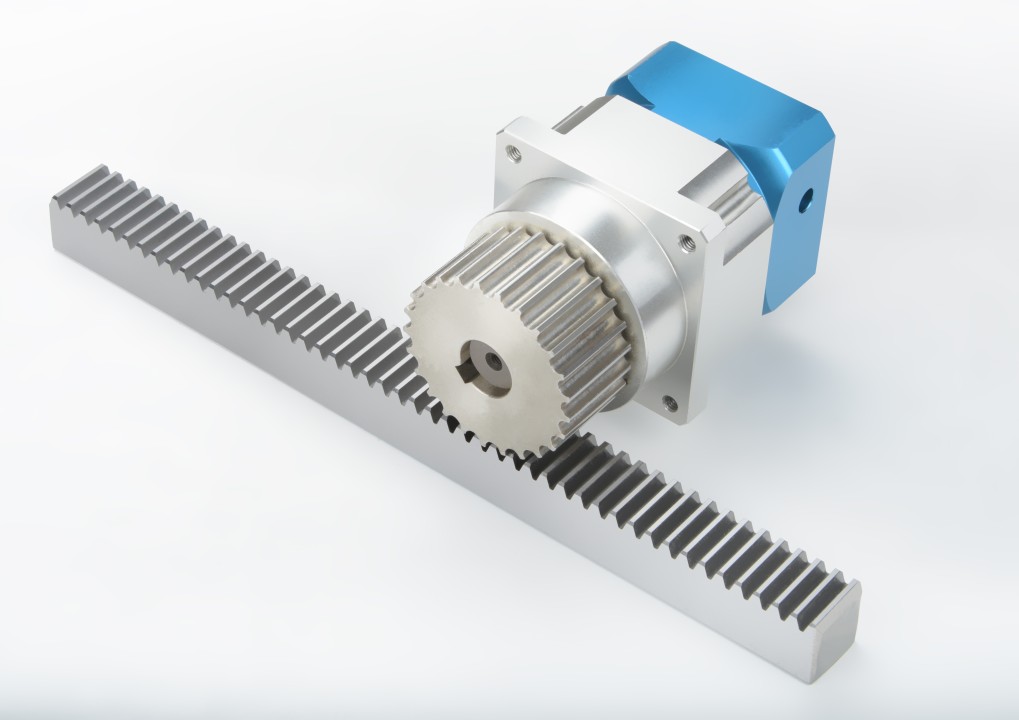

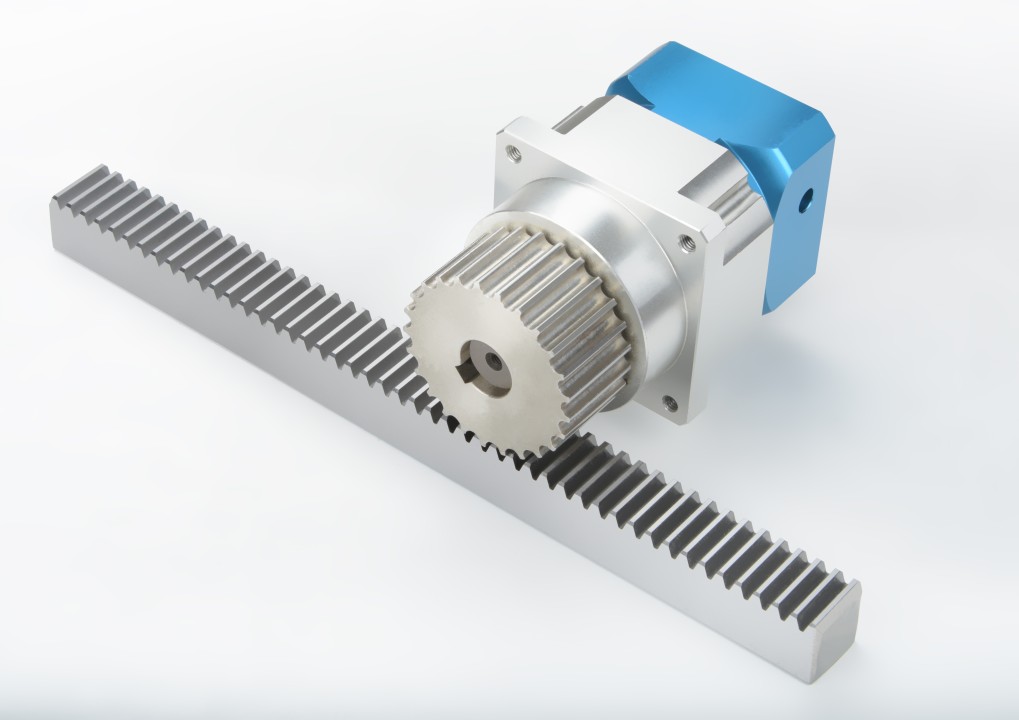

Material:housing -casting iron- HT200-250#/aluminum worm gear-KK alloy worm-20CrMnTi with carburizing and quenching,surface hardness is 58-62HRC shaft-chromium steel-45#

Packing: Inner pack: use plastic bag a Inner pack: use plastic bag and foam box, outer pack: carton or wooden case 1set/bag/carton or based on customer’s requestbearing: CHINAMFG & Homemade bearing

Seal: CHINAMFG seal from ZheJiang

Input power: 0.25kw,0.37kw,0.55kw,0.75kw,1.1kw,1.5kw,2.2kw,3.0kw,4.0kw,5.5kw,7.5kw

Lubricant:Synthetic & Mineral

IEC flange:56B5,63B5,71B5,80B5,90B5,100B5,112B5,132B5

Output form: CHINAMFG shaft,hollow shaft weight: 0.7-87.8KGSapplication: In industrial machine:food Stuff,ceramics,chemical,packing,printing,dyeing,woodworking,glass and plastics

Warranty:1 year

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery |

|---|---|

| Function: | Speed Changing, Speed Reduction |

| Layout: | helical |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Four-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the durability of pulley gearboxes in industrial environments?

Manufacturers take several measures to ensure the durability of pulley gearboxes in industrial environments. These measures involve careful design, material selection, manufacturing processes, and quality control. Here’s a detailed explanation of how manufacturers ensure the durability of pulley gearboxes:

Robust Design: Manufacturers employ robust design practices to ensure that pulley gearboxes can withstand the demands of industrial environments. The gearbox is designed to handle the anticipated loads, torque, and operating conditions specific to the intended application. Factors such as appropriate housing design, proper alignment of pulley shafts, and reinforcement in critical areas are taken into account during the design phase to enhance the durability and reliability of the gearbox.

Material Selection: Careful selection of materials is crucial for ensuring the durability of pulley gearboxes. Manufacturers choose materials that exhibit high strength, wear resistance, and corrosion resistance to withstand the harsh operating conditions in industrial environments. Components such as pulleys, shafts, bearings, and housings are typically made from materials such as steel alloys, cast iron, or aluminum, depending on the specific application requirements and environmental factors.

Quality Manufacturing Processes: Manufacturers employ precise and quality manufacturing processes to produce pulley gearboxes that meet stringent standards. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, ensure accurate dimensions and proper fitment of components. The gearbox components are manufactured with tight tolerances to ensure smooth operation and minimize friction. Additionally, manufacturers follow industry best practices and quality control measures to ensure consistent and reliable production of gearboxes.

Proper Lubrication: Lubrication is critical for the smooth operation and durability of pulley gearboxes. Manufacturers specify appropriate lubricants for the gearbox based on factors such as load, speed, temperature, and operating environment. Adequate lubrication reduces friction, minimizes wear on components, dissipates heat, and helps prevent corrosion. Manufacturers may provide guidelines for the recommended lubrication schedule and type of lubricant to be used, and users are advised to follow these recommendations for optimal gearbox performance and durability.

Testing and Validation: Manufacturers subject pulley gearboxes to rigorous testing and validation procedures to ensure their durability. These tests may include load testing, endurance testing, temperature testing, and performance evaluation under various operating conditions. Testing helps identify potential weaknesses or design flaws, allowing manufacturers to make necessary improvements to enhance the durability and reliability of the gearboxes. Compliance with industry standards and regulations is also an important aspect of the testing and validation process.

Environmental Protection: In industrial environments, pulley gearboxes may be exposed to dust, debris, moisture, or other contaminants that can impact their durability. Manufacturers address this by incorporating protective measures into the gearbox design. This may include sealing mechanisms to prevent ingress of contaminants, such as dust seals or labyrinth seals, as well as the use of coatings or surface treatments to enhance corrosion resistance. These protective measures help extend the lifespan of the gearbox and maintain its performance in challenging environments.

User Education and Support: Manufacturers often provide user manuals, technical documentation, and support to ensure that users understand how to operate and maintain the pulley gearbox properly. This includes information on recommended maintenance practices, lubrication procedures, and troubleshooting guidelines. By educating users about the gearbox’s operational requirements, manufacturers help optimize its durability and minimize the risk of premature failure.

By implementing these measures, manufacturers aim to ensure that pulley gearboxes can withstand the demanding conditions of industrial environments and provide long-lasting, reliable performance.

What factors should be considered when selecting the right pulley gearbox for an application?

When selecting the right pulley gearbox for an application, several factors need to be considered to ensure optimal performance, efficiency, and compatibility. Here’s a detailed explanation of the factors that should be taken into account:

- Load Requirements: One of the primary factors to consider is the load requirements of the application. This includes factors such as the magnitude of the load, whether it is a constant or variable load, and the torque requirements. Understanding the load characteristics helps determine the appropriate pulley sizes, gear ratios, and torque capabilities needed for the gearbox.

- Speed Requirements: The desired speed range and speed control requirements are crucial considerations. Determine the required speed ratios and the range of speeds the application demands. This helps in selecting the appropriate pulley sizes and configurations to achieve the desired speed variations and control.

- Space Constraints and Design: Consider the available space for installing the pulley gearbox. Assess the dimensions and design of the gearbox to ensure it can be accommodated within the given space constraints. Additionally, evaluate the mounting options and compatibility with the application’s mechanical layout.

- Efficiency and Power Transmission: Evaluate the efficiency of the pulley gearbox to ensure minimal power losses during transmission. Higher efficiency contributes to better overall system performance and reduced energy consumption. Consider factors such as friction losses, belt or rope materials, and the quality of the pulley gearbox components.

- Environmental Factors: Take into account any environmental conditions that may impact the performance and longevity of the pulley gearbox. Factors such as temperature extremes, humidity, dust, and corrosive substances should be considered. Choose a pulley gearbox with appropriate sealing, cooling mechanisms, and materials that can withstand the specific environmental conditions of the application.

- Operational Durability and Maintenance: Consider the expected duty cycle and operational lifespan of the pulley gearbox. Assess the reliability, durability, and maintenance requirements of the gearbox components, including bearings, lubrication systems, and seals. A gearbox that requires minimal maintenance and offers long-term reliability can contribute to cost savings and uninterrupted operation.

- Budget and Cost: Evaluate the budget constraints and cost-effectiveness of the pulley gearbox. Compare different options, considering factors such as initial purchase cost, maintenance requirements, and potential energy savings. Balancing the desired performance with the available budget is essential in selecting the right pulley gearbox.

- Application-Specific Considerations: Lastly, consider any application-specific requirements or standards that need to be met. Certain industries or applications may have specific regulations or performance criteria that the pulley gearbox must adhere to. Ensure that the selected gearbox meets the necessary standards and requirements.

By carefully considering these factors, it becomes possible to select the right pulley gearbox that meets the specific requirements of the application, ensuring optimal performance, efficiency, and longevity.

Can you explain the different types of pulley gearboxes and their specific functions?

There are several different types of pulley gearboxes, each with its specific functions and applications. These variations in design and configuration allow pulley gearboxes to cater to diverse requirements in power transmission and speed control. Here’s an explanation of the different types of pulley gearboxes and their specific functions:

- Fixed Ratio Pulley Gearbox: This type of pulley gearbox consists of two pulleys of different sizes that are fixed to their respective shafts. The driving pulley and the driven pulley are connected by a belt or rope. The fixed ratio pulley gearbox is primarily used for speed conversion, where the rotational speed is either increased or decreased while maintaining a constant ratio between the input and output shafts. It is commonly employed in applications where a specific speed conversion is required, such as in conveyor systems or certain types of machinery.

- Variable Ratio Pulley Gearbox: Also known as a variable speed pulley gearbox or a stepless transmission, this type of gearbox allows for continuous and stepless variation of the speed ratio between the input and output shafts. It typically consists of two conical pulleys connected by a V-belt or a similar mechanism. By adjusting the distance between the two pulleys, the effective diameter of the pulleys changes, resulting in variable speed ratios. Variable ratio pulley gearboxes are commonly used in applications that require smooth and precise speed control, such as in automotive transmissions, industrial machinery, and exercise equipment.

- Compound Pulley Gearbox: A compound pulley gearbox utilizes multiple pulleys arranged in a series or parallel configuration to achieve complex speed and torque conversions. It involves intermediate pulleys and idler pulleys to redirect the belt or rope path. Compound pulley gearboxes offer versatility in speed control and power transmission, allowing for a wide range of speed and torque ratios. They find applications in various industrial systems, including complex machinery, assembly lines, and material handling equipment.

- Reversible Pulley Gearbox: This type of pulley gearbox is designed to provide bidirectional power transmission. It typically consists of two pulleys of the same size connected by a belt or rope. By shifting the belt or rope to different positions on the pulleys, the direction of power transmission can be reversed. Reversible pulley gearboxes are commonly used in applications where the ability to change the direction of rotation is required, such as in winches, hoists, and certain types of machinery.

- Step-Up and Step-Down Pulley Gearbox: Step-up and step-down pulley gearboxes are designed to either increase or decrease the rotational speed and torque between the input and output shafts. Step-up pulley gearboxes have a smaller driving pulley and a larger driven pulley, resulting in higher output speed and lower torque. They are used in applications where high-speed operation is required, such as in certain types of machine tools. Step-down pulley gearboxes have a larger driving pulley and a smaller driven pulley, resulting in lower output speed and higher torque. They are commonly used in applications that require high torque, such as in heavy-duty machinery and equipment.

The specific functions of pulley gearboxes are determined by their design, configuration, and the requirements of the application. By selecting the appropriate type of pulley gearbox, engineers and designers can achieve the desired speed control, power transmission, and adaptability for a wide range of industrial applications.

editor by CX 2024-03-15