Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

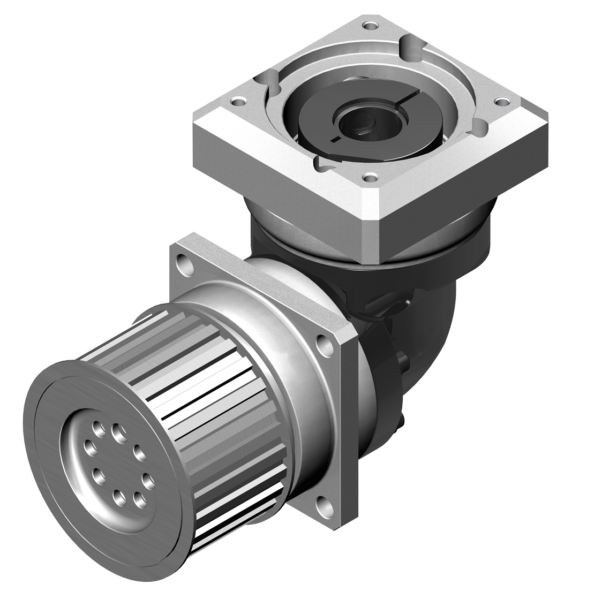

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How do pulley gearboxes contribute to energy efficiency and reduced power consumption?

Pulley gearboxes play a significant role in improving energy efficiency and reducing power consumption in various mechanical systems. They achieve this through several mechanisms and advantages inherent to their design and operation. Here’s a detailed explanation of how pulley gearboxes contribute to energy efficiency and reduced power consumption:

Speed Reduction: One of the primary functions of pulley gearboxes is to reduce the rotational speed of the input shaft while increasing the torque at the output shaft. This speed reduction allows the driven equipment to operate at a lower speed without sacrificing the required torque. By slowing down the rotational speed, pulley gearboxes enable the use of smaller and more efficient motors or engines, which consume less power compared to their high-speed counterparts. This speed reduction mechanism contributes to energy savings in applications where high speeds are not necessary.

Torque Multiplication: Pulley gearboxes also provide torque multiplication, allowing higher torque to be delivered at the output shaft compared to the input shaft. This torque multiplication capability enables the use of smaller and more efficient motors or engines that can operate at lower torque levels. By reducing the torque demand on the driving source, such as an electric motor, pulley gearboxes help optimize power consumption and improve overall energy efficiency.

Efficient Power Transfer: Pulley gearboxes employ belts or chains to transmit power between the input and output shafts. These flexible power transmission elements have the advantage of dampening vibrations and reducing noise compared to direct gear-to-gear mechanisms. The use of belts or chains also helps to mitigate shock loads and minimize backlash, resulting in smoother power transmission. The reduced mechanical losses and improved power transfer efficiency contribute to energy savings and increased overall system efficiency.

Variable Speed Control: Pulley gearboxes, especially those with adjustable pulley sizes or multiple stages, offer the advantage of variable speed control. By adjusting the position of the belt on the pulleys or changing the gear ratio, the output speed can be easily modified to match the requirements of the driven equipment or process. This variable speed control capability allows for optimal operation in different load conditions, avoiding unnecessary energy consumption at higher speeds when lower speeds would suffice. By adapting the speed to the specific needs of the application, pulley gearboxes contribute to energy efficiency and reduced power consumption.

Load Matching: Pulley gearboxes facilitate load matching, which means optimizing the speed and torque characteristics of the output shaft to match the requirements of the driven load. By selecting the appropriate pulley sizes or gear ratios, the pulley gearbox can be tailored to provide the right combination of speed and torque for the specific application. This load matching capability ensures that the driven equipment operates at its most efficient point, minimizing energy losses and reducing power consumption.

Power Loss Minimization: Pulley gearboxes are designed to minimize power losses resulting from friction and mechanical inefficiencies. Manufacturers employ various techniques to improve the efficiency of pulley gearboxes, such as using high-quality bearings, optimizing gear tooth profiles, reducing internal clearances, and selecting low-friction materials. These design considerations help minimize power losses and maximize energy transfer efficiency, thereby reducing power consumption.

System Optimization: Pulley gearboxes are often integrated into larger mechanical systems where the overall system efficiency is critical. By providing the necessary speed reduction, torque multiplication, and load matching capabilities, pulley gearboxes enable the optimization of the entire system. This optimization may involve selecting the most efficient motor, engine, or prime mover, as well as optimizing the sizing and selection of other components in the system. By contributing to system efficiency, pulley gearboxes play a vital role in reducing overall power consumption.

It is important to note that the energy efficiency and power consumption of pulley gearboxes depend not only on their design and operation but also on other factors such as the application, load conditions, maintenance, and the overall system design. Collaborating with experienced engineers and manufacturers can help ensure the proper selection, sizing, and utilization of pulley gearboxes to achieve the desired energy efficiency and power savings.

What factors should be considered when selecting the right pulley gearbox for an application?

When selecting the right pulley gearbox for an application, several factors need to be considered to ensure optimal performance, efficiency, and compatibility. Here’s a detailed explanation of the factors that should be taken into account:

- Load Requirements: One of the primary factors to consider is the load requirements of the application. This includes factors such as the magnitude of the load, whether it is a constant or variable load, and the torque requirements. Understanding the load characteristics helps determine the appropriate pulley sizes, gear ratios, and torque capabilities needed for the gearbox.

- Speed Requirements: The desired speed range and speed control requirements are crucial considerations. Determine the required speed ratios and the range of speeds the application demands. This helps in selecting the appropriate pulley sizes and configurations to achieve the desired speed variations and control.

- Space Constraints and Design: Consider the available space for installing the pulley gearbox. Assess the dimensions and design of the gearbox to ensure it can be accommodated within the given space constraints. Additionally, evaluate the mounting options and compatibility with the application’s mechanical layout.

- Efficiency and Power Transmission: Evaluate the efficiency of the pulley gearbox to ensure minimal power losses during transmission. Higher efficiency contributes to better overall system performance and reduced energy consumption. Consider factors such as friction losses, belt or rope materials, and the quality of the pulley gearbox components.

- Environmental Factors: Take into account any environmental conditions that may impact the performance and longevity of the pulley gearbox. Factors such as temperature extremes, humidity, dust, and corrosive substances should be considered. Choose a pulley gearbox with appropriate sealing, cooling mechanisms, and materials that can withstand the specific environmental conditions of the application.

- Operational Durability and Maintenance: Consider the expected duty cycle and operational lifespan of the pulley gearbox. Assess the reliability, durability, and maintenance requirements of the gearbox components, including bearings, lubrication systems, and seals. A gearbox that requires minimal maintenance and offers long-term reliability can contribute to cost savings and uninterrupted operation.

- Budget and Cost: Evaluate the budget constraints and cost-effectiveness of the pulley gearbox. Compare different options, considering factors such as initial purchase cost, maintenance requirements, and potential energy savings. Balancing the desired performance with the available budget is essential in selecting the right pulley gearbox.

- Application-Specific Considerations: Lastly, consider any application-specific requirements or standards that need to be met. Certain industries or applications may have specific regulations or performance criteria that the pulley gearbox must adhere to. Ensure that the selected gearbox meets the necessary standards and requirements.

By carefully considering these factors, it becomes possible to select the right pulley gearbox that meets the specific requirements of the application, ensuring optimal performance, efficiency, and longevity.

What is a pulley gearbox and how does it function in mechanical systems?

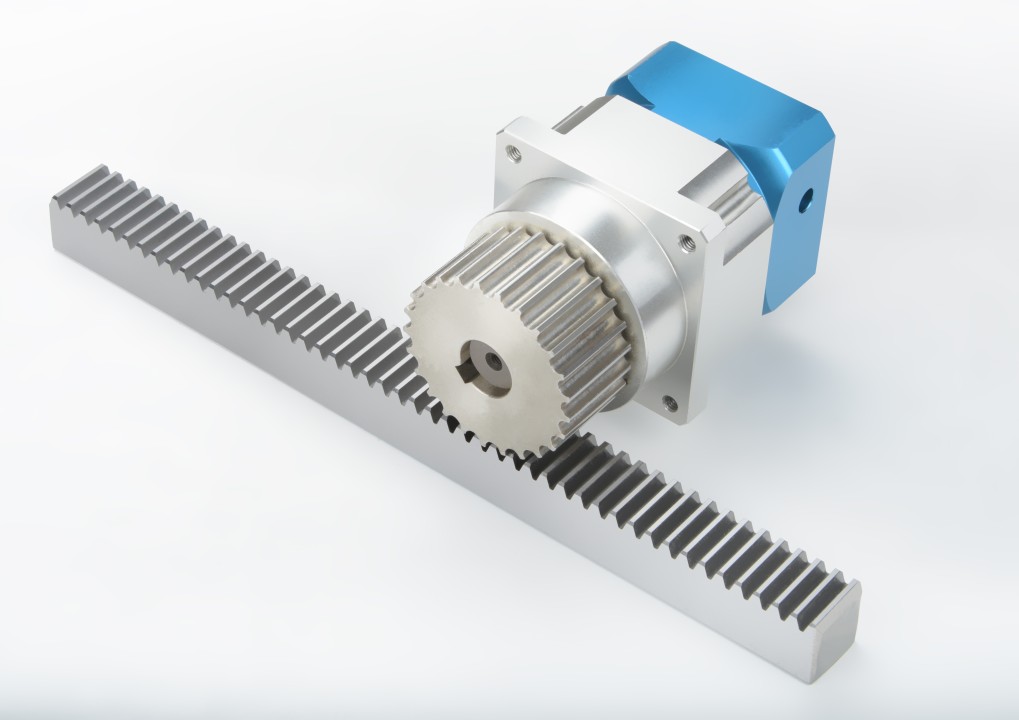

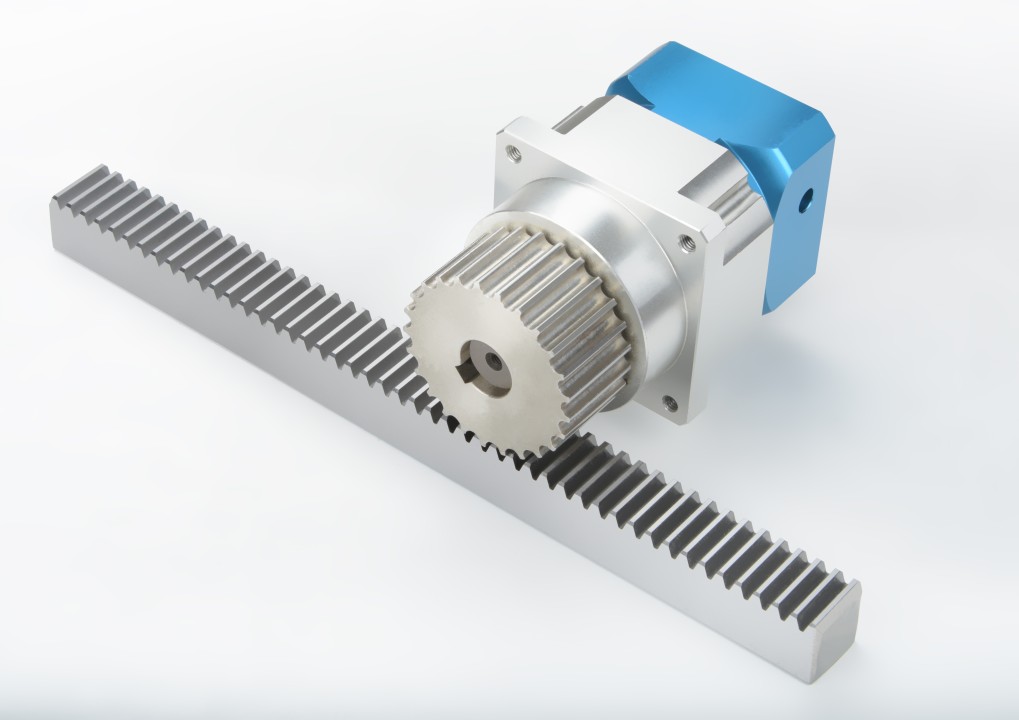

A pulley gearbox, also known as a pulley system or pulley transmission, is a mechanical device that utilizes pulleys and belts or ropes to transmit power and torque between rotating shafts. It functions by changing the speed and direction of rotation while maintaining a constant power output. Here’s a detailed explanation of the pulley gearbox and its functioning in mechanical systems:

Definition and Components:

A pulley gearbox consists of several components, including pulleys, belts or ropes, and a tensioning mechanism. The pulleys are circular wheels with grooves along their circumference to hold the belts or ropes. The belts or ropes are flexible elements that wrap around the pulleys, forming a loop. The tensioning mechanism ensures proper tension in the belts or ropes to prevent slippage and ensure efficient power transmission.

Speed and Torque Conversion:

The primary function of a pulley gearbox is to convert the speed and torque between two rotating shafts. This is achieved by using pulleys of different sizes. The size of a pulley is determined by its diameter. The larger the diameter of a pulley, the slower it rotates, and vice versa. By connecting pulleys of different sizes with belts or ropes, the rotational speed can be increased or decreased, allowing for speed conversion in the mechanical system.

When the driving pulley (connected to the input shaft) has a smaller diameter than the driven pulley (connected to the output shaft), the speed is increased, but the torque is reduced. This configuration is referred to as an speed increaser or speed-up pulley system. Conversely, when the driving pulley has a larger diameter than the driven pulley, the speed is decreased, but the torque is increased. This configuration is referred to as a speed reducer or speed-down pulley system.

Multiple Pulley Configurations:

Pulley gearboxes can be designed with multiple pulleys and belts or ropes to create more complex speed and torque conversion systems. These configurations can involve additional intermediate pulleys and idler pulleys to redirect the belt or rope path. By combining pulleys of different sizes and arranging them in various configurations, the pulley gearbox can achieve specific speed and torque ratios to suit the requirements of the mechanical system.

Advantages and Applications:

The pulley gearbox offers several advantages in mechanical systems:

- Simplicity: Pulley gearboxes are relatively simple in design and construction, making them cost-effective and easy to manufacture.

- Smooth Operation: The use of belts or ropes in the pulley system helps absorb shocks and vibrations, resulting in smoother operation and reduced noise.

- Adjustability: The speed ratio of a pulley gearbox can be easily adjusted by changing the sizes of the pulleys, allowing for flexibility in adapting to different operational requirements.

- Non-slip Power Transmission: The friction between the belts or ropes and the pulleys ensures efficient power transmission without slippage, even under varying load conditions.

- Compact Size: Pulley gearboxes can be designed in compact sizes, making them suitable for applications where space is limited.

Pulley gearboxes find applications in various mechanical systems, including conveyor systems, industrial machinery, agricultural equipment, automotive accessories, exercise machines, and more. They are particularly useful in situations where speed and torque conversion, adjustability, and smooth power transmission are required.

editor by CX 2023-10-25