Product Description

SC Transmission SMR Series Shaft Mounted Gearbox

for Belt Conveyor and Pulley drives

Product Description

Components:

1. Housing: High-strength Gray Cast Iron Gearboxes

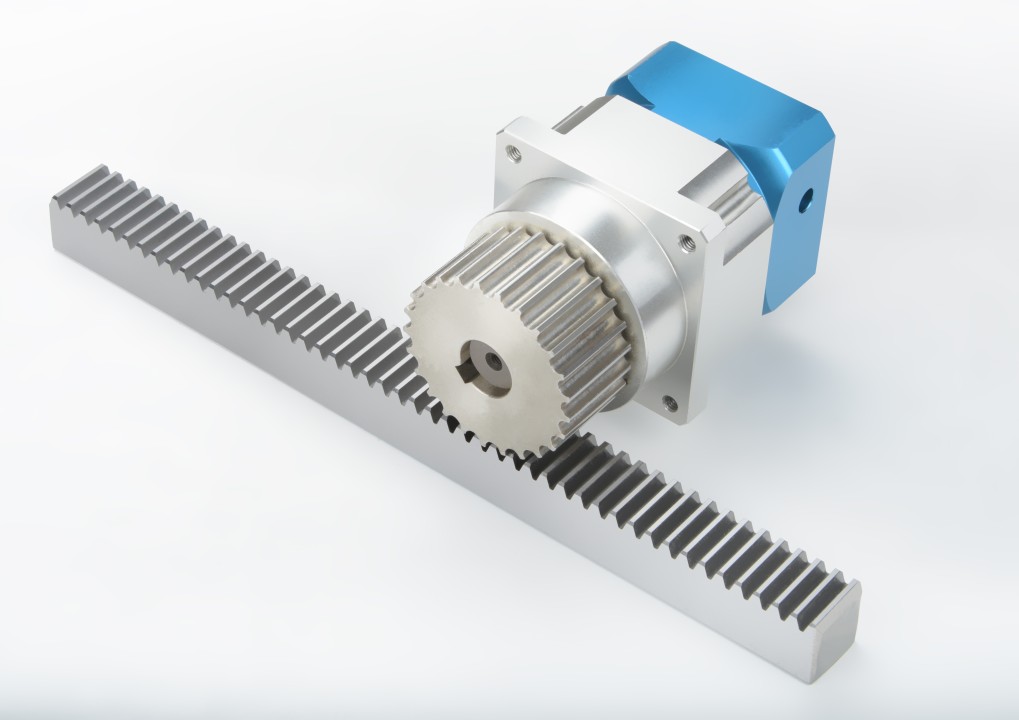

2. Gears: Helical Involute Gears, Carburizing, Quenching, Grinding

3. Shafts: High-strength Hardening Alloy Steel

4. Input Configurations:

Keyed CZPT Shaft Input

5. Output Configurations:

Keyed Hollow Shaft Output

6. Oil Seal: Double Lips Skeleton Seal

7. Spare Parts: Torque arm, Optional Backstop

Models:

1 Stage(Ratio 5): B05, C05, D05, E05, F05, G05, H05, J05

2 Stage(Ratio 13/20): B13/20, C13/20, D13/20, E13/20, F13/20, G13/20, H13/20, J13/20

Features:

1. High strength of gear box, gears and shafts, sturdy and durable

2. 2 metric output shaft bore diameters(Standard and Optional)

3. Optional backstop to prevent backdriving. Backstop is not recommended for the gear ratio 5

4. Double lips skeleton oil seal combines the functions of seal and dust-proof

5. Widely used in belt conveyor and pulley drive system

Product Parameters

Parameters:

| Models | Output Shaft Bore | Max. Torque* | Nominal Ratio | |

| Standard | Optional | |||

| SMR-B | 30mm | 40mm | 277N.m | 5 13 20 |

| SMR-C | 40mm | 50mm | 468N.m | |

| SMR-D | 50mm | 55mm | 783N.m | |

| SMR-E | 55mm | 65mm | 1194N.m | |

| SMR-F | 65mm | 75mm | 1881N.m | |

| SMR-G | 75mm | 85mm | 2970N.m | |

| SMR-H | 85mm | 100mm | 4680N.m | |

| SMR-J | 100mm | 120mm | 7449N.m | |

*Max. Torque for output speed 100RPM

Applications:

Conveyors in Mine, Quarry, CZPT Transport, Baggage & Bulk Handling, Animal Feeding, etc.

Installation:

1. Hanging Shaft Mounted

2. Output Flange Mounted

Lubrication:

Oil-bath and Splash Lubrication

Lubricating Oil: Mineral Oil and Synthetic Oil

Extreme pressure oil is not recommended, unless in case of with backstop

Cooling:

Natural Cooling

Detailed Photos

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Layout: | Shunting |

| Gear Shape: | Helical Involute Gears |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do pulley gearboxes handle variations in speed ratios and torque requirements?

Pulley gearboxes are designed to handle variations in speed ratios and torque requirements by utilizing different pulley sizes, configurations, and mechanical principles. They offer flexibility and adaptability in adjusting speed and torque according to specific application needs. Here’s a detailed explanation of how pulley gearboxes handle variations in speed ratios and torque requirements:

Pulley Size and Configuration:

Pulley gearboxes employ pulleys of different sizes and configurations to achieve the desired speed ratios and torque requirements. By varying the diameters of the driving and driven pulleys, the

What factors should be considered when selecting the right pulley gearbox for an application?

When selecting the right pulley gearbox for an application, several factors need to be considered to ensure optimal performance, efficiency, and compatibility. Here’s a detailed explanation of the factors that should be taken into account:

- Load Requirements: One of the primary factors to consider is the load requirements of the application. This includes factors such as the magnitude of the load, whether it is a constant or variable load, and the torque requirements. Understanding the load characteristics helps determine the appropriate pulley sizes, gear ratios, and torque capabilities needed for the gearbox.

- Speed Requirements: The desired speed range and speed control requirements are crucial considerations. Determine the required speed ratios and the range of speeds the application demands. This helps in selecting the appropriate pulley sizes and configurations to achieve the desired speed variations and control.

- Space Constraints and Design: Consider the available space for installing the pulley gearbox. Assess the dimensions and design of the gearbox to ensure it can be accommodated within the given space constraints. Additionally, evaluate the mounting options and compatibility with the application’s mechanical layout.

- Efficiency and Power Transmission: Evaluate the efficiency of the pulley gearbox to ensure minimal power losses during transmission. Higher efficiency contributes to better overall system performance and reduced energy consumption. Consider factors such as friction losses, belt or rope materials, and the quality of the pulley gearbox components.

- Environmental Factors: Take into account any environmental conditions that may impact the performance and longevity of the pulley gearbox. Factors such as temperature extremes, humidity, dust, and corrosive substances should be considered. Choose a pulley gearbox with appropriate sealing, cooling mechanisms, and materials that can withstand the specific environmental conditions of the application.

- Operational Durability and Maintenance: Consider the expected duty cycle and operational lifespan of the pulley gearbox. Assess the reliability, durability, and maintenance requirements of the gearbox components, including bearings, lubrication systems, and seals. A gearbox that requires minimal maintenance and offers long-term reliability can contribute to cost savings and uninterrupted operation.

- Budget and Cost: Evaluate the budget constraints and cost-effectiveness of the pulley gearbox. Compare different options, considering factors such as initial purchase cost, maintenance requirements, and potential energy savings. Balancing the desired performance with the available budget is essential in selecting the right pulley gearbox.

- Application-Specific Considerations: Lastly, consider any application-specific requirements or standards that need to be met. Certain industries or applications may have specific regulations or performance criteria that the pulley gearbox must adhere to. Ensure that the selected gearbox meets the necessary standards and requirements.

By carefully considering these factors, it becomes possible to select the right pulley gearbox that meets the specific requirements of the application, ensuring optimal performance, efficiency, and longevity.

rotational speed can be adjusted. Larger driving pulleys and smaller driven pulleys result in a higher speed ratio, while smaller driving pulleys and larger driven pulleys lead to a lower speed ratio. The selection of pulley sizes allows for precise control over speed variations in pulley gearboxes.

Mechanical Advantage:

The mechanical advantage provided by pulley gearboxes allows them to handle variations in torque requirements. Pulley gearboxes utilize the principle of mechanical advantage, where the larger pulley transfers more torque to the smaller pulley. This allows the gearbox to increase or decrease the torque output while maintaining a consistent speed ratio. By adjusting the pulley sizes and the mechanical advantage, pulley gearboxes can match the torque requirements of the driven machinery or system.

Tension and Friction:

Tension and friction play a crucial role in how pulley gearboxes handle variations in speed ratios and torque requirements. The tension in the belts or ropes connecting the driving and driven pulleys helps maintain a firm grip and prevent slippage, ensuring reliable power transmission. By adjusting the tension, the efficiency of power transmission can be optimized. The friction between the belts or ropes and the pulleys also contributes to the handling of torque variations. The frictional force allows for the transfer of torque from the driving pulley to the driven pulley, accommodating changes in torque requirements.

Adjustability:

Pulley gearboxes offer adjustability, allowing for variations in speed ratios and torque requirements. The pulleys can be moved or adjusted to change the effective diameter or position, altering the speed and torque output. This adjustability enables precise control over the performance of the gearbox, making it adaptable to different operational needs and load conditions.

Compound Pulley Systems:

Compound pulley systems are another mechanism used in pulley gearboxes to handle variations in speed ratios and torque requirements. These systems consist of multiple pulleys arranged in series or parallel configurations, incorporating intermediate pulleys and idler pulleys. The compound pulley systems allow for complex speed and torque conversions, providing a wider range of speed ratios and torque capabilities.

Overall, pulley gearboxes handle variations in speed ratios and torque requirements through a combination of pulley size and configuration, mechanical advantage, tension and friction control, adjustability, and the utilization of compound pulley systems. These features enable pulley gearboxes to efficiently transmit power, control speed, and adapt to different operational demands in a wide range of industrial applications.

editor by CX 2023-09-04