Product Description

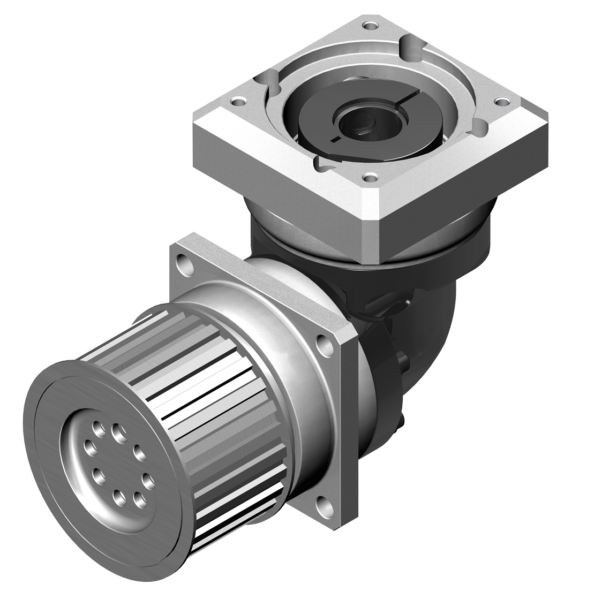

The S-series gearbox is a product of SEW-EURODRIVE It is a right-angle speed reducer with a helical gear and worm gear combined drive system, designed and optimized according to international standards. The S-series gearbox provides higher efficiency than worm gearboxes and also lower noise during operation It is widely applied in robots, CNC machines, welding equipment, plastic machines, packaging and printing machinery, textile and dyeing machinery, construction machinery, communications, and other fields, especially suitable for frequent starting occasions

The S-series gearbox is available in several sizes and design variants, including foot-mounted, flange-mounted, and torque arm-mounted options. Input can be provided through a motor, an IEC flange input, or a shaft input. Output can be provided through a CHINAMFG shaft or a hollow shaft

The housing of the S-series gearbox is made of HT250 high-strength cast iron. The worm gear is made of high-quality copper, while the gears are made of 20CrMnTi. The surface hardness of the gears is HRC58-62. The input/output shaft is made of 40Cr steel. The gearbox undergoes carburizing and quenching heat treatment to improve its durability

The bearings used in the S-series gearbox are from C&U or other reputable brands. The oil seal is from CHINAMFG or other reputable brands. The lubricating oil used in the gearbox is gear oil. The gearbox is packed in a plywood case for safe transportation

The S-series gearbox has several features that make it an attractive choice for many applications. Its simple design makes it cost-effective. It has strong vibration absorption capabilities and operates at low temperatures. It also operates with low noise levels. A wide range of speed ratios is available to choose from. The gearbox can function on its own under certain conditions. It has good sealing properties and is resistant to corrosion, making it suitable for use in harsh conditions. It can also be combined with the R series helical gear reducer for additional functionality

In summary, the S-series gearbox from SEW-EURODRIVE is a versatile and reliable right-angle speed reducer that provides high efficiency and low noise operation. Its wide range of design variants and options make it suitable for use in many different applications, especially those that require frequent starting. Its robust construction and high-quality materials ensure its durability and longevity.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How do pulley gearboxes contribute to optimizing the efficiency of conveyor systems?

Pulley gearboxes play a crucial role in optimizing the efficiency of conveyor systems, which are widely used in industries for material handling and transportation. By providing speed control, torque multiplication, and efficient power transmission, pulley gearboxes offer several benefits that contribute to the overall efficiency of conveyor systems. Here’s a detailed explanation of how pulley gearboxes optimize conveyor system efficiency:

Speed Control: One of the key advantages of pulley gearboxes in conveyor systems is their ability to control the rotational speed of the conveyor belt. By adjusting the pulley sizes or changing the gear ratio, the speed of the conveyor belt can be precisely regulated to match the specific requirements of the application. This speed control capability allows for optimal material handling, preventing unnecessary energy consumption or strain on the system. For instance, in situations where lighter loads or delicate materials are being transported, the speed can be reduced to avoid excessive impact or spillage. On the other hand, for heavy loads or time-sensitive operations, the speed can be increased to maximize productivity. By adapting the speed to the specific needs of the material and operation, pulley gearboxes optimize the efficiency of conveyor systems.

Torque Multiplication: Pulley gearboxes are designed to provide torque multiplication, allowing higher torque to be delivered at the output pulley compared to the input pulley. This torque multiplication capability is particularly beneficial in conveyor systems that handle heavy loads or encounter resistance during operation. By multiplying the torque, pulley gearboxes enable the conveyor system to overcome these challenges more effectively, reducing the risk of belt slippage or motor overload. The increased torque also allows for the use of smaller and more efficient motors, contributing to energy savings and improved efficiency. Torque multiplication provided by pulley gearboxes ensures that the conveyor system operates at its optimal performance level, enhancing overall efficiency.

Efficient Power Transmission: Pulley gearboxes utilize belts or chains to transmit power from the input pulley to the output pulley. These flexible power transmission elements offer several advantages for conveyor systems. Firstly, they absorb vibrations and dampen shocks, reducing the impact on the system components and improving overall reliability. Secondly, belts or chains allow for slight misalignments and flexibility in the conveyor system, compensating for variations and ensuring smooth operation. Furthermore, the use of belts or chains helps to minimize noise generation during operation. Overall, the efficient power transmission provided by pulley gearboxes ensures minimal power losses and maximizes the energy transfer to the conveyor belt, optimizing the efficiency of the system.

Load Matching: Conveyor systems often encounter variations in load conditions, with different weights and types of materials being transported. Pulley gearboxes enable load matching by allowing for the adjustment of speed and torque output to match the specific load requirements. By selecting the appropriate pulley sizes or gear ratios, the pulley gearbox can be optimized to deliver the necessary speed and torque for efficient material handling. This load matching capability ensures that the conveyor system operates at its most efficient point, minimizing energy losses and reducing power consumption. It also helps to prevent unnecessary wear and tear on the system components, prolonging their lifespan and reducing maintenance requirements.

System Integration: Pulley gearboxes are integrated components within conveyor systems, designed to work seamlessly with other system elements. This integration allows for efficient power transfer and synchronization between the motor, pulleys, and conveyor belt. The proper selection and sizing of pulley gearboxes, along with other components such as motors, bearings, and belts, contribute to the overall efficiency of the conveyor system. By ensuring that all system elements work together harmoniously, pulley gearboxes optimize the performance and energy consumption of the conveyor system as a whole.

Maintenance and Reliability: Efficient maintenance practices and reliable operation are crucial for optimizing the efficiency of conveyor systems. Pulley gearboxes are designed to be durable and require minimal maintenance. Regular inspection and lubrication of the gearboxes help ensure smooth operation and minimize friction losses. Additionally, pulley gearboxes are often equipped with features such as seals and guards to protect against contaminants and prevent premature wear. By maintaining the reliability and performance of the pulley gearboxes, conveyor systems can operate at their highest efficiency, reducing downtime and optimizing productivity.

In summary, pulley gearboxes contribute to optimizing the efficiency of conveyor systems by providing speed control, torque multiplication, efficient power transmission, load matching, and seamless integration with other system components. By leveraging these advantages, conveyor systems can operate at their optimal performance levels, minimizing energy consumption, reducing downtime, and maximizing productivity.

What factors should be considered when selecting the right pulley gearbox for an application?

When selecting the right pulley gearbox for an application, several factors need to be considered to ensure optimal performance, efficiency, and compatibility. Here’s a detailed explanation of the factors that should be taken into account:

- Load Requirements: One of the primary factors to consider is the load requirements of the application. This includes factors such as the magnitude of the load, whether it is a constant or variable load, and the torque requirements. Understanding the load characteristics helps determine the appropriate pulley sizes, gear ratios, and torque capabilities needed for the gearbox.

- Speed Requirements: The desired speed range and speed control requirements are crucial considerations. Determine the required speed ratios and the range of speeds the application demands. This helps in selecting the appropriate pulley sizes and configurations to achieve the desired speed variations and control.

- Space Constraints and Design: Consider the available space for installing the pulley gearbox. Assess the dimensions and design of the gearbox to ensure it can be accommodated within the given space constraints. Additionally, evaluate the mounting options and compatibility with the application’s mechanical layout.

- Efficiency and Power Transmission: Evaluate the efficiency of the pulley gearbox to ensure minimal power losses during transmission. Higher efficiency contributes to better overall system performance and reduced energy consumption. Consider factors such as friction losses, belt or rope materials, and the quality of the pulley gearbox components.

- Environmental Factors: Take into account any environmental conditions that may impact the performance and longevity of the pulley gearbox. Factors such as temperature extremes, humidity, dust, and corrosive substances should be considered. Choose a pulley gearbox with appropriate sealing, cooling mechanisms, and materials that can withstand the specific environmental conditions of the application.

- Operational Durability and Maintenance: Consider the expected duty cycle and operational lifespan of the pulley gearbox. Assess the reliability, durability, and maintenance requirements of the gearbox components, including bearings, lubrication systems, and seals. A gearbox that requires minimal maintenance and offers long-term reliability can contribute to cost savings and uninterrupted operation.

- Budget and Cost: Evaluate the budget constraints and cost-effectiveness of the pulley gearbox. Compare different options, considering factors such as initial purchase cost, maintenance requirements, and potential energy savings. Balancing the desired performance with the available budget is essential in selecting the right pulley gearbox.

- Application-Specific Considerations: Lastly, consider any application-specific requirements or standards that need to be met. Certain industries or applications may have specific regulations or performance criteria that the pulley gearbox must adhere to. Ensure that the selected gearbox meets the necessary standards and requirements.

By carefully considering these factors, it becomes possible to select the right pulley gearbox that meets the specific requirements of the application, ensuring optimal performance, efficiency, and longevity.

Can you explain the different types of pulley gearboxes and their specific functions?

There are several different types of pulley gearboxes, each with its specific functions and applications. These variations in design and configuration allow pulley gearboxes to cater to diverse requirements in power transmission and speed control. Here’s an explanation of the different types of pulley gearboxes and their specific functions:

- Fixed Ratio Pulley Gearbox: This type of pulley gearbox consists of two pulleys of different sizes that are fixed to their respective shafts. The driving pulley and the driven pulley are connected by a belt or rope. The fixed ratio pulley gearbox is primarily used for speed conversion, where the rotational speed is either increased or decreased while maintaining a constant ratio between the input and output shafts. It is commonly employed in applications where a specific speed conversion is required, such as in conveyor systems or certain types of machinery.

- Variable Ratio Pulley Gearbox: Also known as a variable speed pulley gearbox or a stepless transmission, this type of gearbox allows for continuous and stepless variation of the speed ratio between the input and output shafts. It typically consists of two conical pulleys connected by a V-belt or a similar mechanism. By adjusting the distance between the two pulleys, the effective diameter of the pulleys changes, resulting in variable speed ratios. Variable ratio pulley gearboxes are commonly used in applications that require smooth and precise speed control, such as in automotive transmissions, industrial machinery, and exercise equipment.

- Compound Pulley Gearbox: A compound pulley gearbox utilizes multiple pulleys arranged in a series or parallel configuration to achieve complex speed and torque conversions. It involves intermediate pulleys and idler pulleys to redirect the belt or rope path. Compound pulley gearboxes offer versatility in speed control and power transmission, allowing for a wide range of speed and torque ratios. They find applications in various industrial systems, including complex machinery, assembly lines, and material handling equipment.

- Reversible Pulley Gearbox: This type of pulley gearbox is designed to provide bidirectional power transmission. It typically consists of two pulleys of the same size connected by a belt or rope. By shifting the belt or rope to different positions on the pulleys, the direction of power transmission can be reversed. Reversible pulley gearboxes are commonly used in applications where the ability to change the direction of rotation is required, such as in winches, hoists, and certain types of machinery.

- Step-Up and Step-Down Pulley Gearbox: Step-up and step-down pulley gearboxes are designed to either increase or decrease the rotational speed and torque between the input and output shafts. Step-up pulley gearboxes have a smaller driving pulley and a larger driven pulley, resulting in higher output speed and lower torque. They are used in applications where high-speed operation is required, such as in certain types of machine tools. Step-down pulley gearboxes have a larger driving pulley and a smaller driven pulley, resulting in lower output speed and higher torque. They are commonly used in applications that require high torque, such as in heavy-duty machinery and equipment.

The specific functions of pulley gearboxes are determined by their design, configuration, and the requirements of the application. By selecting the appropriate type of pulley gearbox, engineers and designers can achieve the desired speed control, power transmission, and adaptability for a wide range of industrial applications.

editor by CX 2023-10-23